PASS/EQUIP → Working with PASS/EQUIP → Data input → Main data input → Material

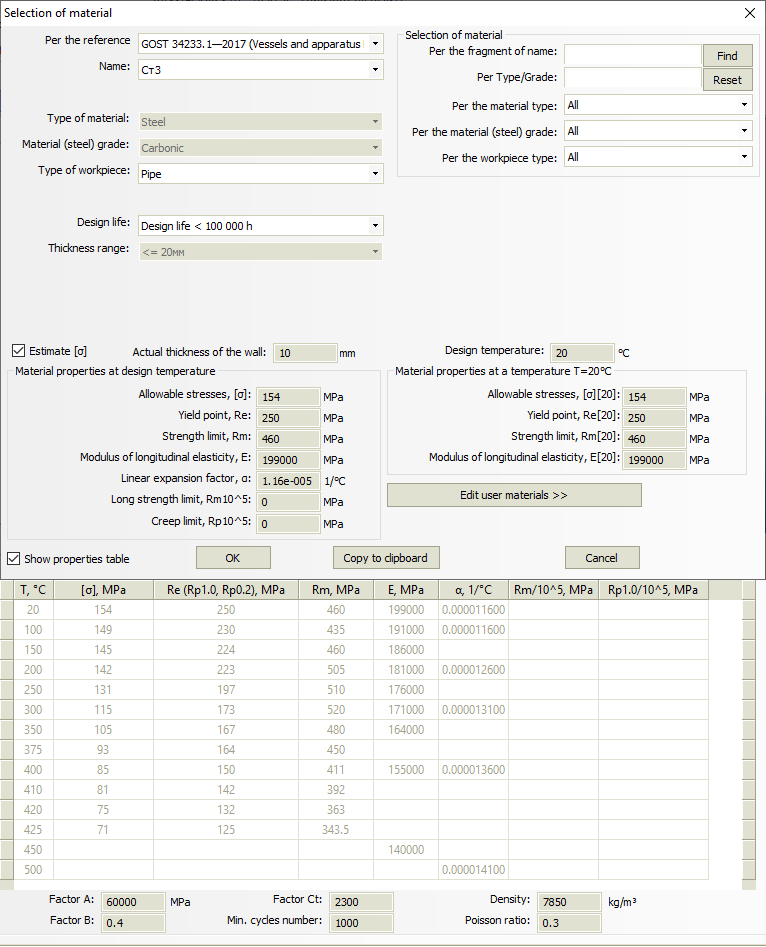

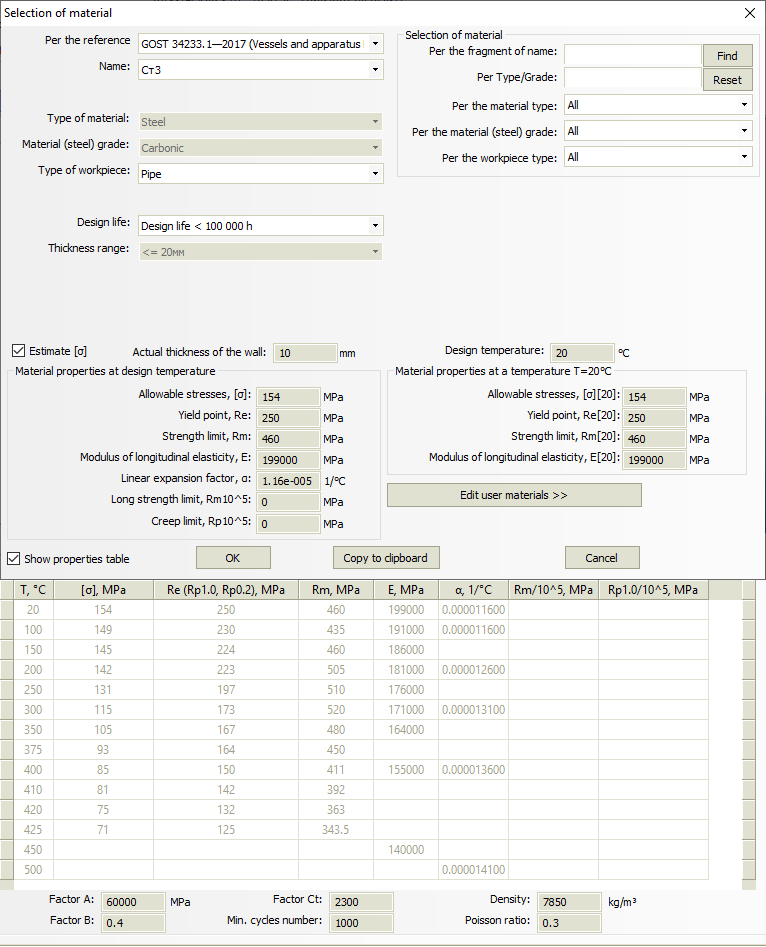

Material selected from database (GOST 34233.1-2017, PNAE G-7-002-86, GOST R 54522-2011, ASME II Part D, EN etc.) or is set by user, where required properties at operating, test and assembling temperature (200 °С) must be set.

Fig. 1. Standard material properties

Material database consists of two parts: group of standard materials and group of user’s materials. First group cannot be changed by user. To edit the second group, “Edit user’s materials” shall be selected.

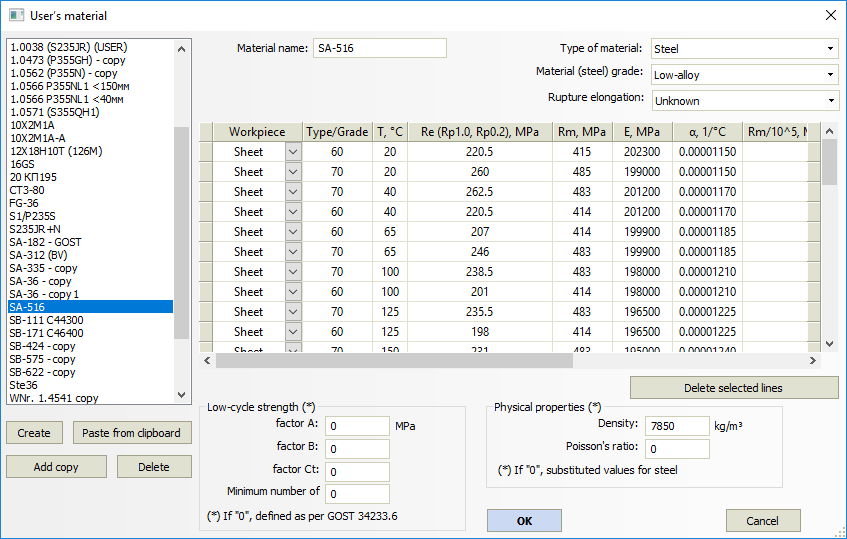

Fig. 2.User defined material properties

In the user’s materials editor the following operations are available:

Adding new “empty” material (“Create”);

Copying table of properties of any of the existing materials as a whole (the command "Copy to clipboard" in the table), and the subsequent insertion to the user material (command "Paste form clipboard");

Deletion of material “highlighted” in the list (”Delete”);

Creation of the new material and copying into it the properties of the material, which is “highlighted” by the cursor in the list (“Add copy”);

Deletion of the group of lines with material properties (“Delete selected lines”);

Material renaming (the name of material is edited in the same field);

Setting of material properties, depending on temperature, thickness, workpiece type, parameters Type/Grade and Class/Condition/Temper (by analogy with ASME II Part D).

After pressing “OK” button a new material will appear in the group “User’s materials”.

Material properties at given temperature are determined by linear interpolation. Data can be set randomly, depending on the temperature — the program will sort them automatically, in the order of temperature increasing. In addition to steel, cast iron, nonferrous metals and titanium alloys can be entered. A and B material properties and correction factor Сt are set for steel, non-ferrous metals, cast iron and titanium alloys when calculating low-cycle fatigue.

If some value is initially equal to 0, then at calculation in will be set automatically, as per GOST 34233.6-2017, based on the material type and grade.

When you add a new material, its properties are saved both in the database and in the model file. When transferring data file to another PC, PASS/EQUIP will read material data and add it to local database if necessary. If a material with the same name already exists in database, properties from the database and not the model file will be used.

In case of simultaneous access of several users to the publicly available database (for example, when it is placed on a network drive), only the first user can edit (for other users, a message appears about the impossibility of editing at the moment).