User Story

Project Name: Isoprene and Isobutylene production facilities design

Company Name: Soyuzkhimpromproyekt

Project Description

| Region | Republic of Tatarstan, Russian Federation |

|---|---|

| Dates | 2016-2018 |

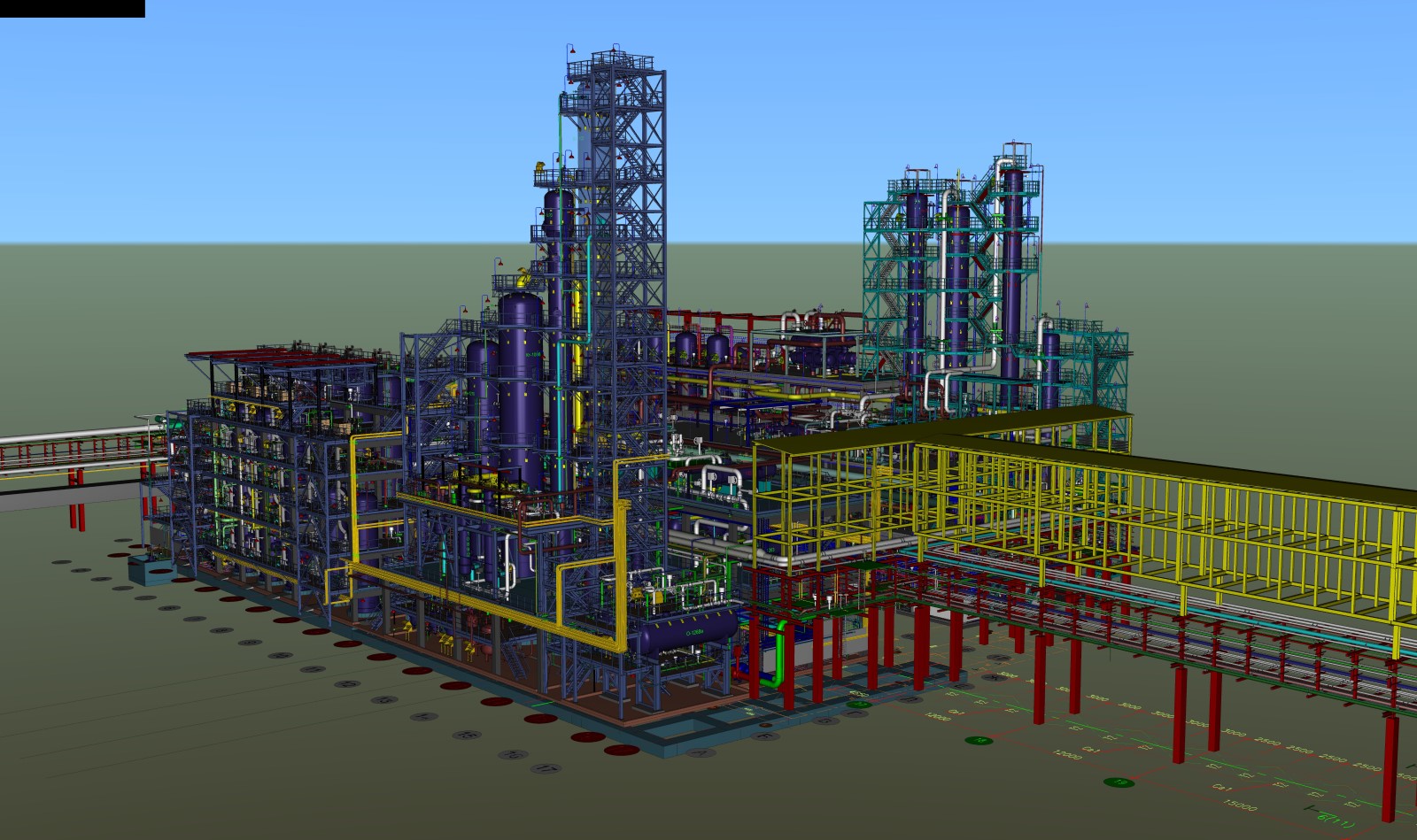

| Scope | The project scope included arrangement of integrated chemical plant units with synthesis reactors in the existing production area, including connection to the utility systems. |

| Project Specific | Project had the following specific:

|

| PASS software used | PASS/HYDROSYSTEM, PASS/START-PROF, PASS/EQUIP, PASS/NOZZLE-FEM |

| How PASS software helped in the project execution | PASS software helped to analyze various arrangement options and select the most convenient ones. The analysis results made it possible to select and place piping and valves properly on the service platforms of columns, and calculate the loads on nozzles and weldolets. |

| Results | Both production facilities were built and put into operation in 2018. The company’s employees familiarity with the PASS software ensured easy and fast performance of analysis of the different options. A reduction in design and construction time, as well as savings in materials and equipment, and support for variability was achieved. |

Company Profile

-

Company nameSoyuzkhimpromproyekt

-

Website

-

Field of activitiesChemical Plant Design

-

Headcount400

Soyuzkhimpromproyekt is an institute focusing on chemical plant design. The institute was organized more than 65 years ago. During this time, the company has gained a deep industry specific expertise.

The Institute has a positive long track record of cooperation with international companies, including FLUOR Corporation, USA; Tecnimont S.p.A, Italy; Mitsubishi Heavy Industries, Japan.