Overview

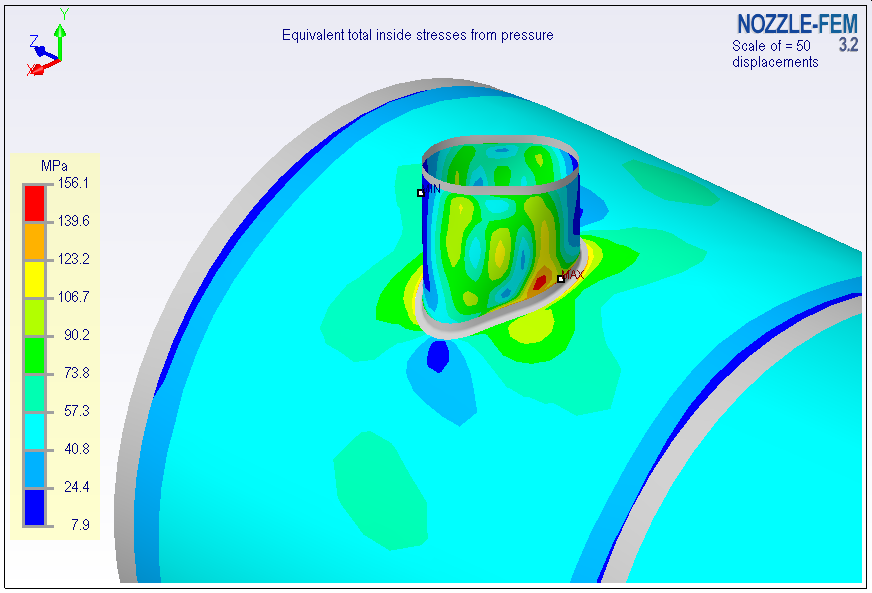

PASS/Nozzle-FEM is designed for stresses and flexibility calculation of nozzle-to-shell junctions using the Finite Element Method (FEM). The program also calculates nozzle’s allowable loads and estimates strength of the nozzle’s junctions for wide range of geometric configurations and operating conditions. Nozzle-FEM helps to provide higher level of the equipment safety along with reducing labour costs at the design stage. The program is recommended for designing and industrial safety review of oil and gas, refining, petrochemical, chemical, power and other industrial facilities.

Unlike the universal FEM programs (ANSYS, NASTRAN, COSMOS, etc.), this program does not require special training and can be used by any mechanical engineer. Creation of finite element mesh and estimation of calculation results are performed automatically. FEM calculation, as opposed to semi-analytic methods (i.e. WRC 107/297, GOST 34233.3-2007, etc.), expands the program application range and increases analysis accuracy.

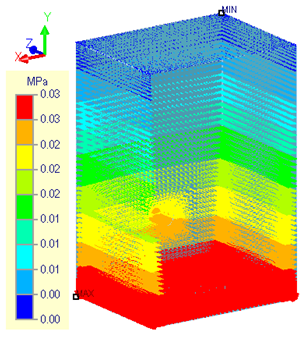

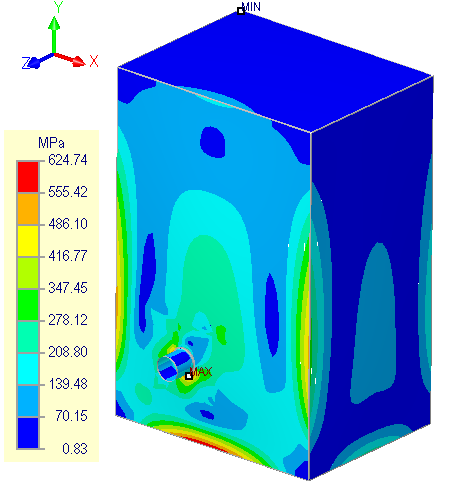

The program performs stress analysis for nozzles (including trunnions) of arbitrary geometry connected to cylindrical and conical shells, as well as elliptic, hemispherical and flat heads. Also one performs stress analysis of special cases: bend stanchion, support skirt, rectangular plate. It takes into account vessel boundary restraints and loads on the nozzle from the adjacent pipeline. Both nozzle and shell membrane, bending and total stresses can be calculated. Calculation of the pipe branch connections is also implemented, enabling detailed stress analysis of non-standard tees and pipelines branch connections.

Along with stress and stability analysis the program also performs nozzle-shell junction flexibility calculation, as this flexibility can considerably influence vessel and piping stresses. During stress analysis of pipeline systems nozzle-vessel junctions are often simulated by anchor supports which leads to overestimation of stresses and tensions. In order to automatically create the appropriate non-standard support in the calculation model, the nozzle-shell junction flexibility calculated by Nozzle-FEM can be passed into the PASS/START-PROF piping stress analysis program.

Powerful capabilities

Allowable stresses calculation according to the rule codes (ASME, EN, JB, GOST etc)

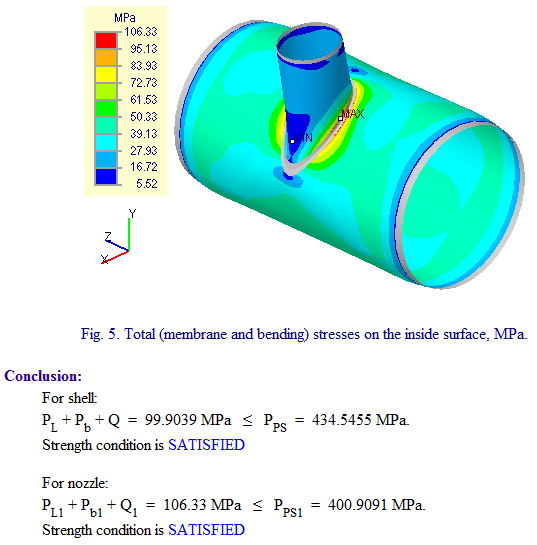

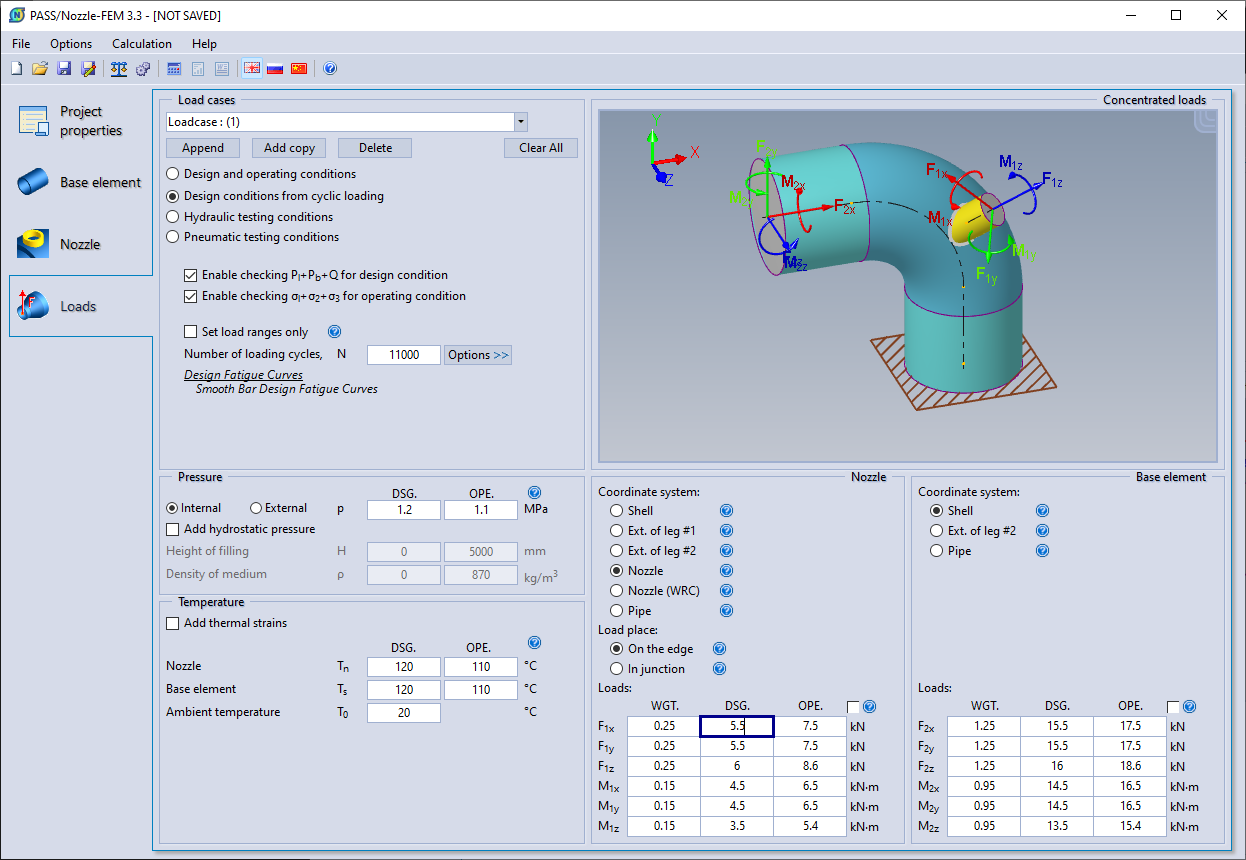

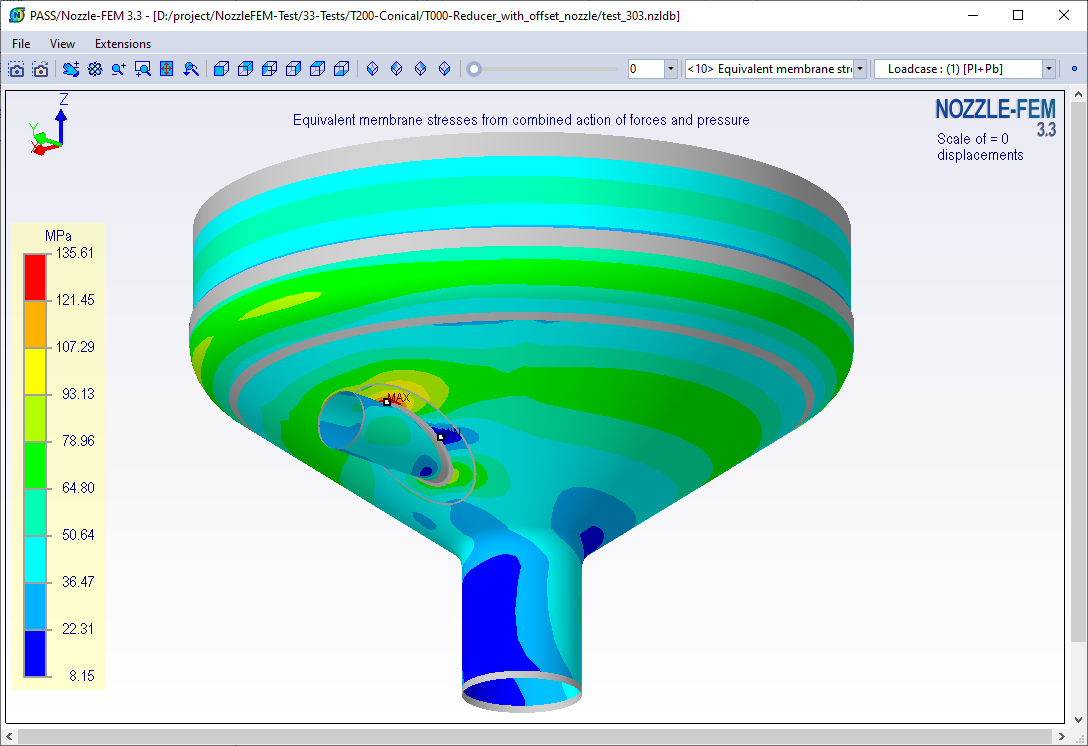

Stress analysis of nozzle-to-shell junction from the action of external loads, pressure and thermal expansion

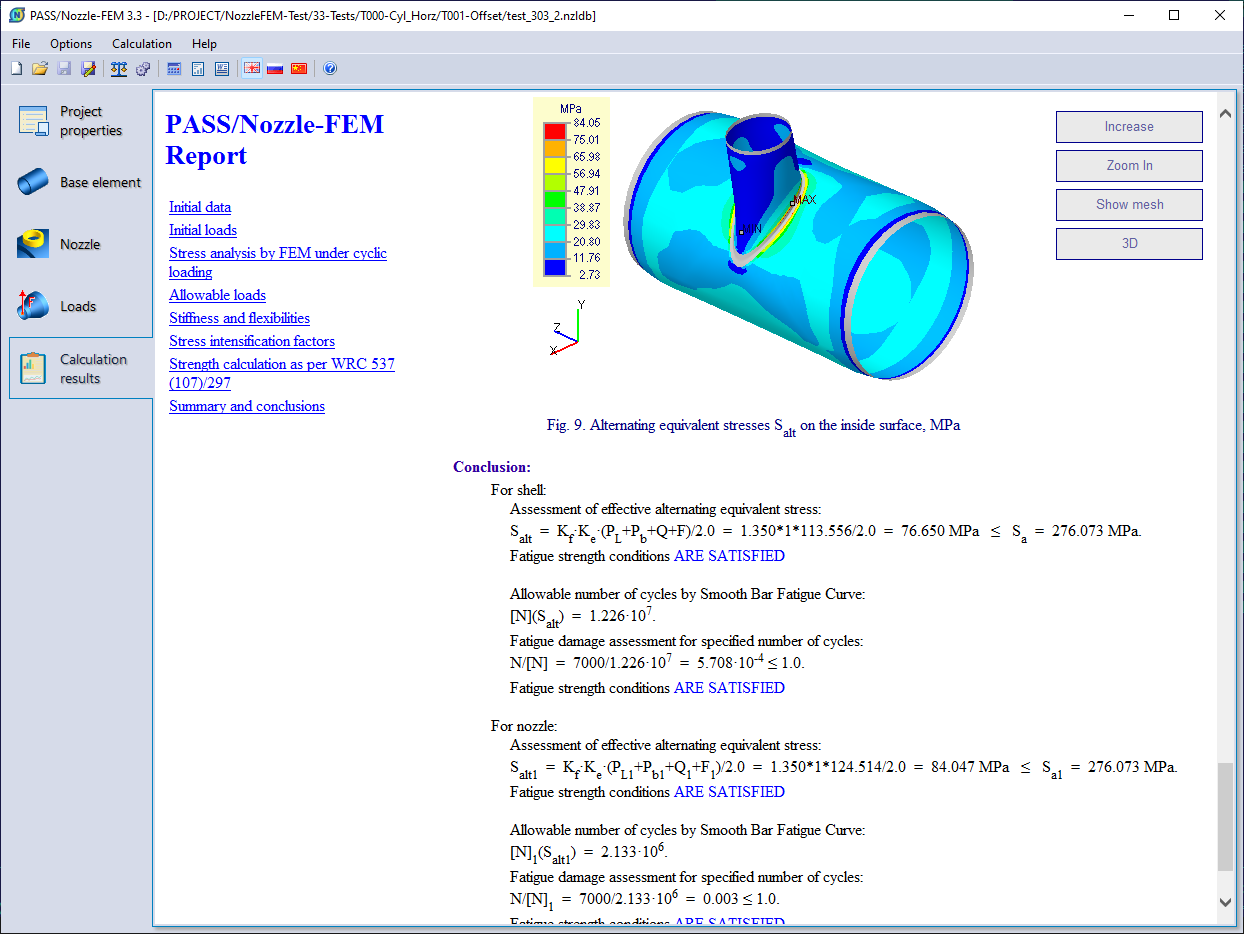

Creating detail report with calculation results and strength conclusions (HTML, RTF)

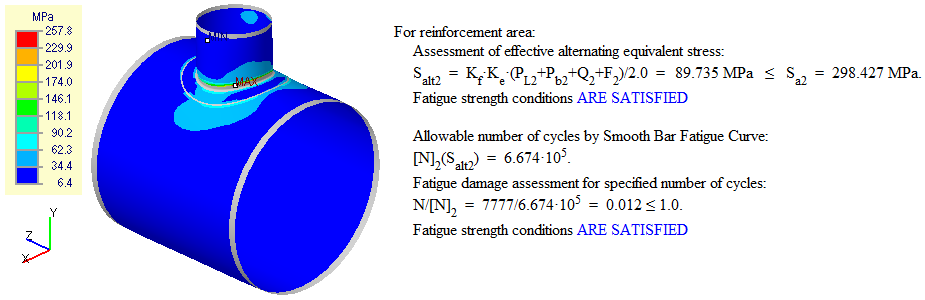

Fatigue assessment according to ASME VIII.2 and GOST

Allowable loads for nozzle\support and unconstrained shell ends

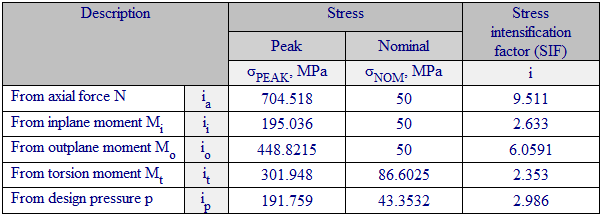

Stress intensification factors (SIF) calculation

Flexibility analysis (stiffness, flexibility factors)

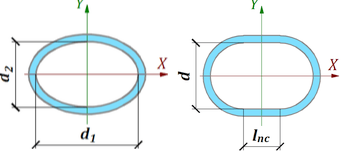

Calculation of nozzle with non-circle cross-section shapes

Calculation of multiple user load cases

Calculation with thermal strains

The program Nozzle-FEM allows to take into account the thermal strains of materials in components that make up the vessel or apparatus. This allows us to take into account the expansion (deformation) of the materials in components under the temperature effects, as well as additional stresses arising from constrained temperature deformations (different linear expansion coefficients, different temperatures, etc).

See Knowledge BaseCalculation with hydrostatic pressure

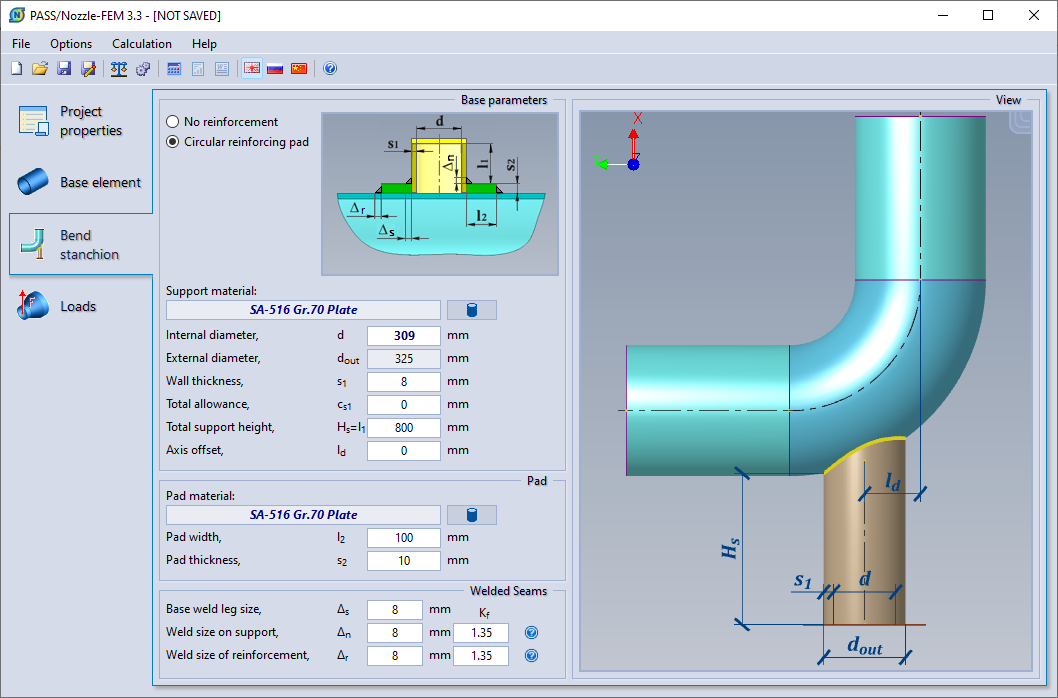

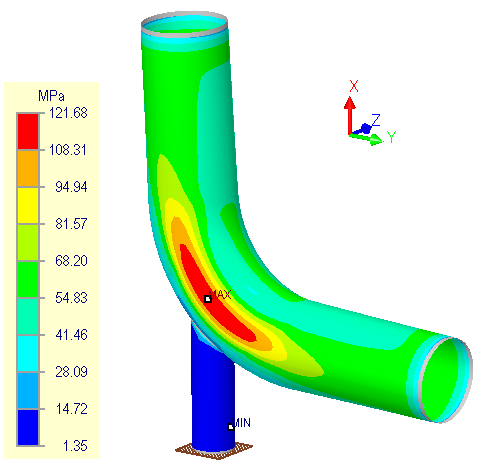

Calculation of bend stanchion

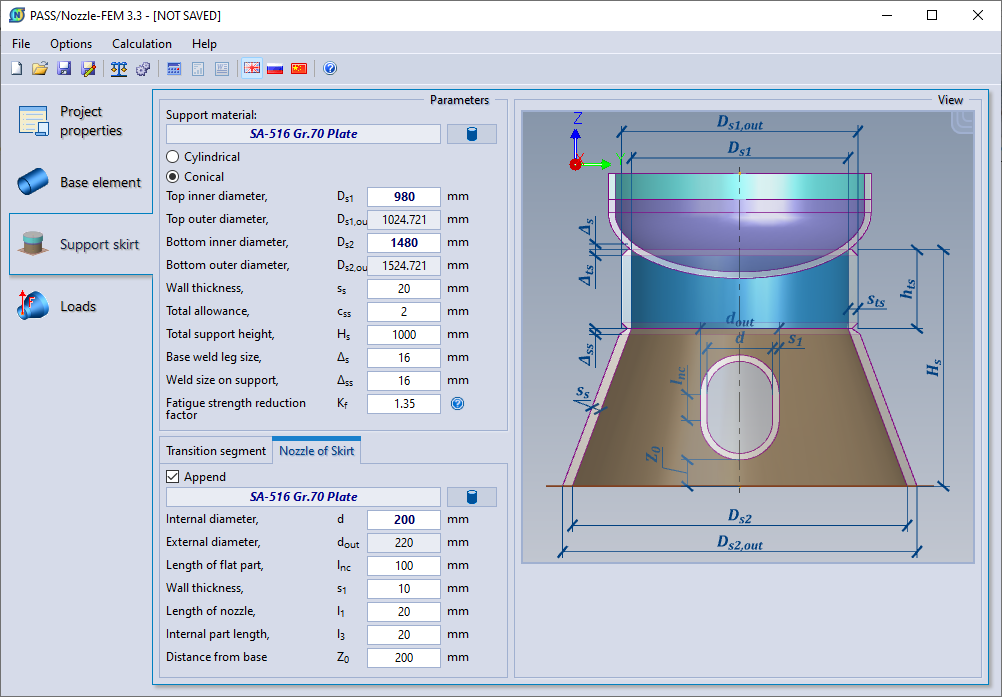

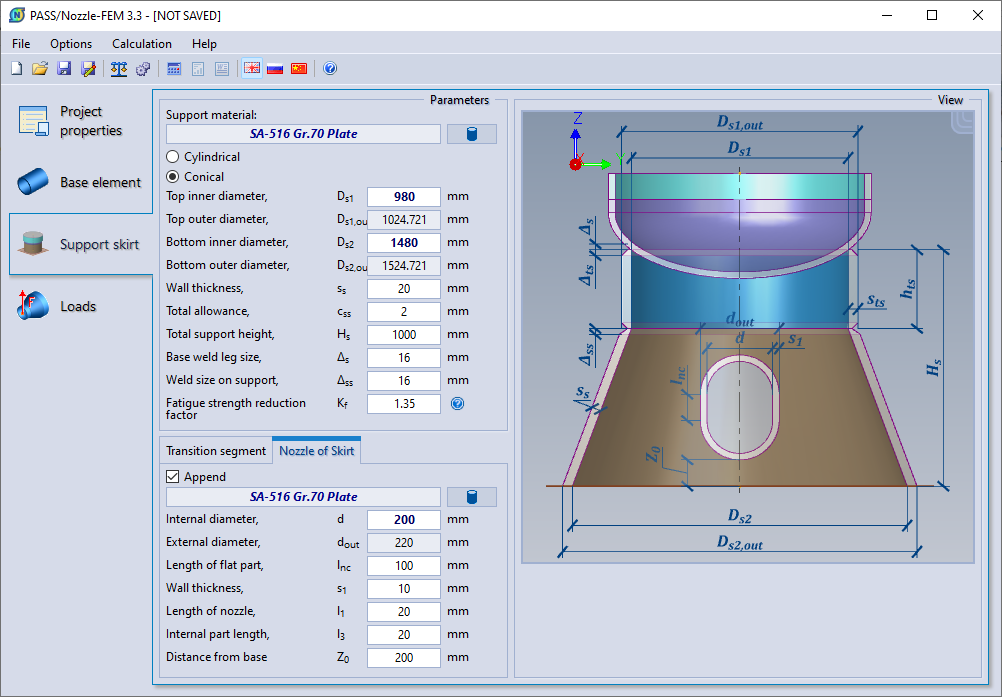

Calculation of support skirt

Calculation of nozzle junction into rectangular wall

Calculation of strength and stiffness as per WRC 537/107(297)

Calculation of hole reinforcement as per GOST 34233.3-2017

Strength analysis in corrosive hydrogen sulphide medium (GOST)

Integration

PASS/Nozzle-FEM model can be created and transferred from PASS/EQUIP software.

The special variant of PASS/Nozzle-FEM has been developed for tie-ins (tees and fittings) and shell-to-nozzle junction calculation as per WRC and GOST, to be called directly from PASS/START-PROF software. Any Nozzle-FEM results can also be user in the piping system analysis by PASS/START-PROF in manual mode.

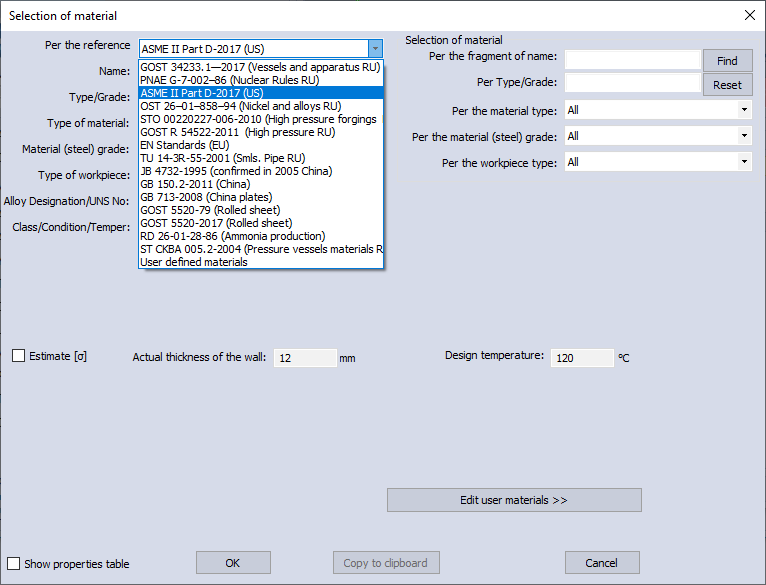

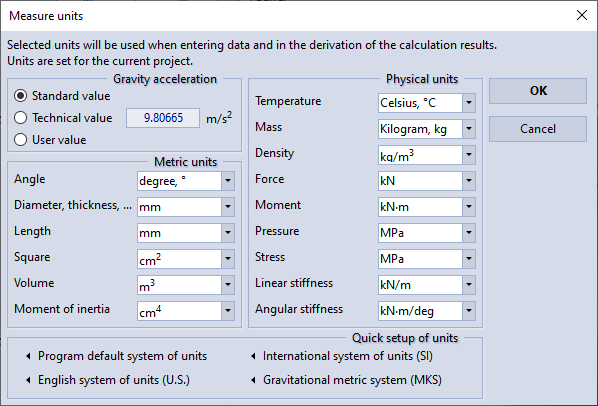

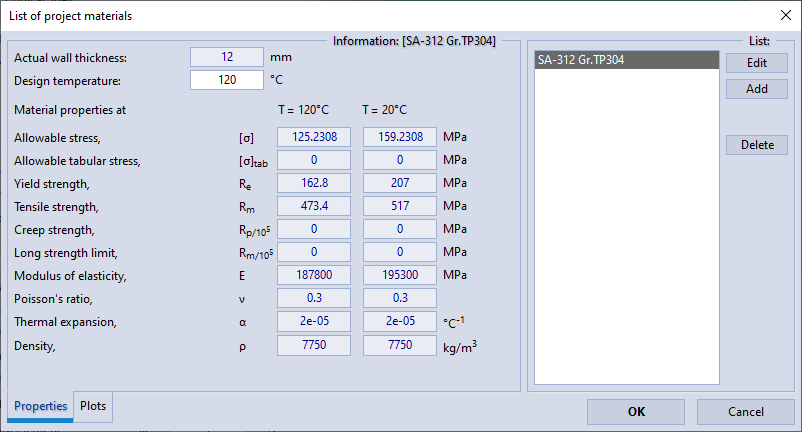

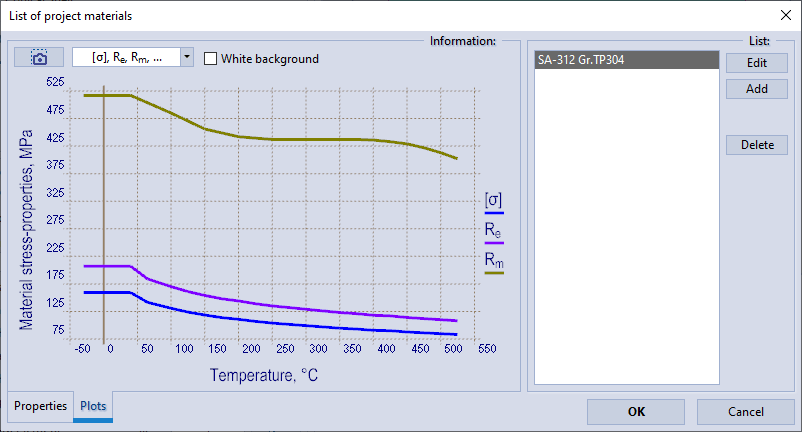

Materials database

The material database includes physical and mechanical properties of vessel elements materials according US, European, Chinese and Russian codes.

User Interface

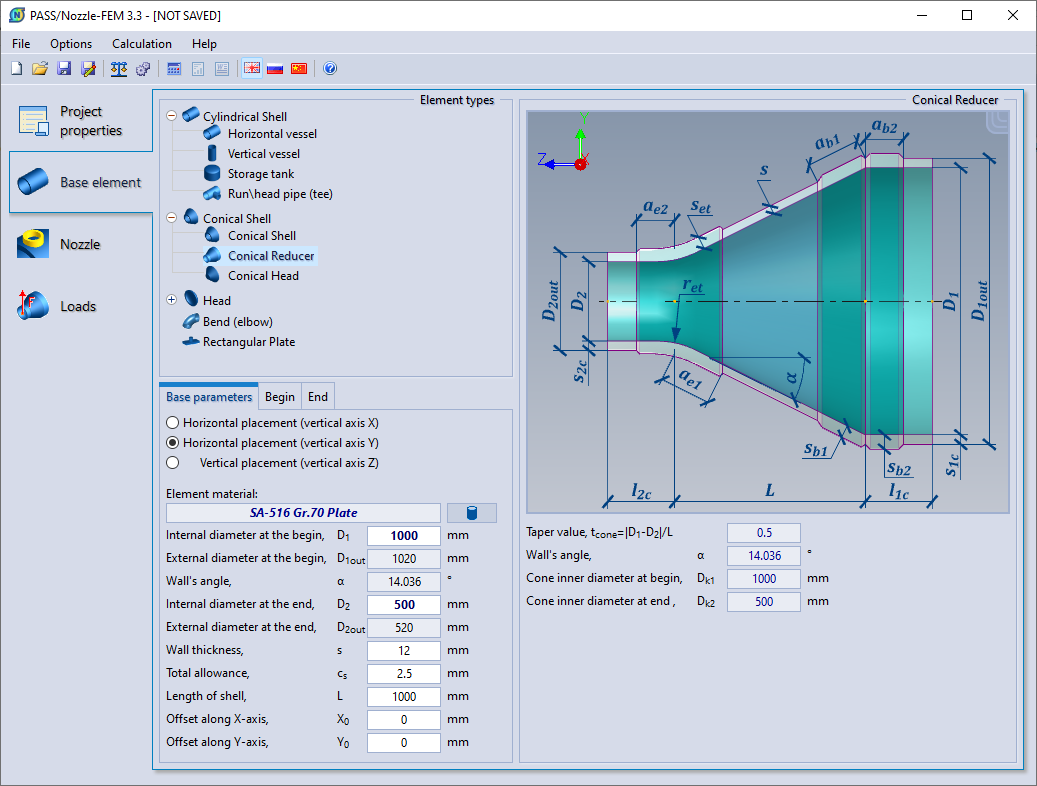

The program has a modern, convenient, easy and friendly graphical user interface (GUI), which includes interactive user tips and user manuals in English and Russian languages.

PASS/Nozzle-FEM allows to create a several base design scheme by attachment element type:

No attachment

The design scheme consists only of a base element.

See Knowledge BaseNozzle (branch)

The design scheme consists of a base element and a nozzle.

See Knowledge BaseBend stanchion

The design scheme simulates a elbow (bend) with support.

See Knowledge BaseSupport skirt

The design scheme allows to simulate the convex head with a skirt support.

See Knowledge BasePASS/Nozzle-FEM allows to model a variety shell elements, which greatly simplifies the design model creation:

Horizontal vessel

Used for modeling of horizontal pressure vessel and etc.

See Knowledge BaseVertical vessel

Used for modeling of vertical pressure vessel.

See Knowledge BaseStorage tank

Used for modeling of vertical storage tank.

See Knowledge BaseRunhead pipe (tee)

Used for modeling incutting to pipe (tee).

See Knowledge BaseConical shell

Used for modeling transition pressure segment with different diameters and etc.

See Knowledge BaseConical reducer

Provides additional capabilites to previous element.

See Knowledge BaseConical head

Used for modeling conical heads.

See Knowledge BaseElliptical head

Convex head under pressure.

See Knowledge BaseHemispherical head

Convex head under pressure.

See Knowledge BaseTorispherical head (dished)

Convex head under pressure.

See Knowledge BaseFlat head

Flat head under pressure.

See Knowledge BaseConical head

Used for modeling conical heads.

See Knowledge BaseBend (elbow)

Used for modeling bending of pipeline.

See Knowledge BaseRectangular plate

Used for modeling incutting to rectangular plate.

See Knowledge BaseSystem Requirements

Codes

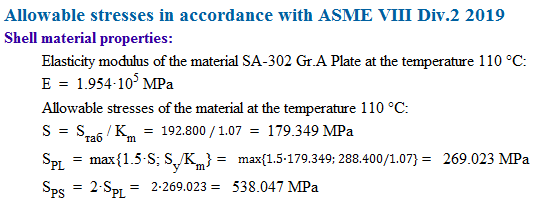

Allowable stresses for finite element method (FEM) analysis are defined by the following codes implemented in Nozzle-FEM:

- ASME Boiler and Pressure Vessel Code. Part D. Properties. Section II, Materials - 2019.

- ASME Boiler and Pressure Vessel Code. Rules for Construction of Pressure Vessels. Section VIII, Division 1 – 2019.

- ASME Boiler and Pressure Vessel Code. Rules for Construction of Pressure Vessels. Section VIII, Division 2 – 2019.

- EN 13445-3. European Standard. Unfired pressure vessels – Part 3. Issue 1 (2002-05).

- JB 4732-1995-EN. Professional Standard of the People's Republic of China – 1995.

- GOST 34233.1-2017. Vessels and apparatuses. Standards and methods of strength calculation. General requirements.

- GOST 34233.6-2017. Vessels and apparatuses. Standards and methods of strength calculation. Strength calculation under low-cyclic loads.

- GOST 34233.10-2017. Vessels and apparatuses. Standards and methods of strength calculation. Vessels and apparatuses operating in hydrogen sulphide environments.

- PNAE G-7-002-86. Standards of strength calculation for equipment and pipelines of nuclear power plants. –M.: Energoatomizdat, 1989.

Besides finite element method calculation, the program supports CIF and flexibility calculation via semi-analytic methods according to WRC 537/107(297) (Welding Research Council Bulletins No. 107, No. 297 “Local stresses in spherical and cylindrical casings caused by the external loads”) and BS5500-76 (British standard).

PASS/Nozzle-FEM performs similar calculations (without FEM analysis) of vessel elements and nozzle junctions as per the following codes:

- WRC-537 Welding Research Council. Bulletin. "Precision Equations and Enhanced diagrams for Local Stresses in Spherical and Cylindrical Shells due to External Loadings for implementation of WRC Bulletin 107". 2013.

- GOST 34233.2-2017. Vessels and apparatuses. Standards and methods of strength calculation. Calculation of cylindrical and conical shells, dished and flat bottoms and covers.

- GOST 34233.3-2017. Vessels and apparatuses. Standards and methods of strength calculation. Reinforcement of openings in shells and heads under internal and external pressure. Strength calculation of shells and heads under external static loads on the nozzle.

Configurations

PASS/NOZZLE-FEM can be delivered in different configurations:

PASS/NOZZLE-FEM

PASS/NOZZLE-FEM provides FEM analysis for nozzle and vessel connections.

PASS/EQUIP FEM Complete

PASS/EQUIP FEM Complete is a bundle that provides comprehensive design by rules and design by FEM analysis. Includes Vessel, Column, Exchanger, Tank & Nozzle analysis.

Download Software

| Software | Link | Upload Date |

|---|---|---|

| PASS/NOZZLE-FEM 3.5.1 (English, Chinese and Spanish) (64 bit) | request |

10.07.2024 |

| PASS/NOZZLE-FEM 3.5.1 (English, Chinese and Spanish) (32 bit) | request |

10.07.2024 |

| PASS/NOZZLE-FEM 3.4.8 (English, Chinese and Spanish) (64 bit) | request |

08.02.2024 |

| PASS/NOZZLE-FEM 3.4.8 (English, Chinese and Spanish) (32 bit) | request |

08.02.2024 |

| LMS (Sentinel HL and Guardant) Tools (only for PASS/NOZZLE-FEM 3.5, PASS/HYDROSYSTEM 4.6 and PASS/EQUIP 3.7) | ||

| Dongle Update Tool (KeySt) for Guardant and Sentinel HL | zip, 16.76 MiB | 09.07.2024 |

| Drivers and network key manager for Sentinel HL dongles (Windows) | exe, 37.14 MiB | 12.12.2023 |

| Drivers for Guardant dongles | exe, 11.43 MiB | 24.12.2021 |

| SuperPro Tools | ||

| Dongle Update (KeySt) | zip, 4.13 MiB | 13.12.2023 |

| Dongle Drivers SafeNet Sentinel 7.6.9 | exe, 7.37 MiB | 13.12.2023 |

Resources

Videos

Supporting Materials

PASS/NOZZLE-FEM. Overview March 2020

PASS/NOZZLE-FEM. Release History

PASS/NOZZLE-FEM. Release History (Spanish)