Overview

PASS/START-PROF provides comprehensive pipe stress, flexibility, stability, and fatigue strength analysis with related sizing calculations according to international and national codes and standards. First introduced in 1965, PASS/START-PROF combines a highly efficient solver, powerful analysis features, a user friendly GUI, an intuitive 3D graphical pre/post-processor, and a detailed help system with embedded intelligence from generations of piping design experts.

Due to modern object-oriented and intuitive user interface in PASS/START-PROF engineers can start working immediately, no need to spend a time for "how to push the buttons" training. Companies can put PASS/START-PROF into application immediately after purchase, significantly reducing costs in time saved without compromising on the quality of end results. Engineers can deliver a good quality pipe stress analysis using PASS/START-PROF with minimal training and guidance.

PASS/START-PROF® – Renowned, one of the first world commercial piping stress analysis software.

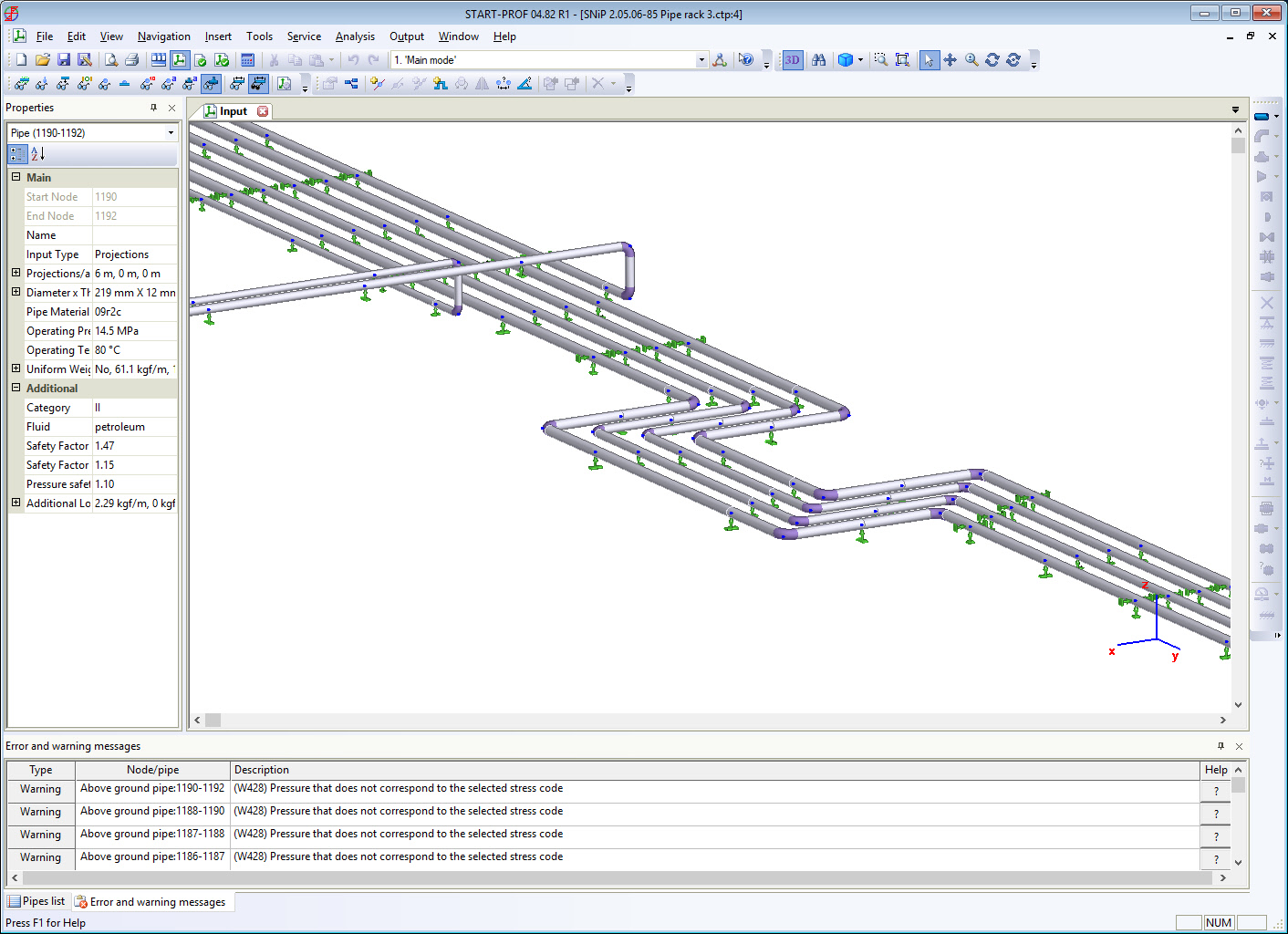

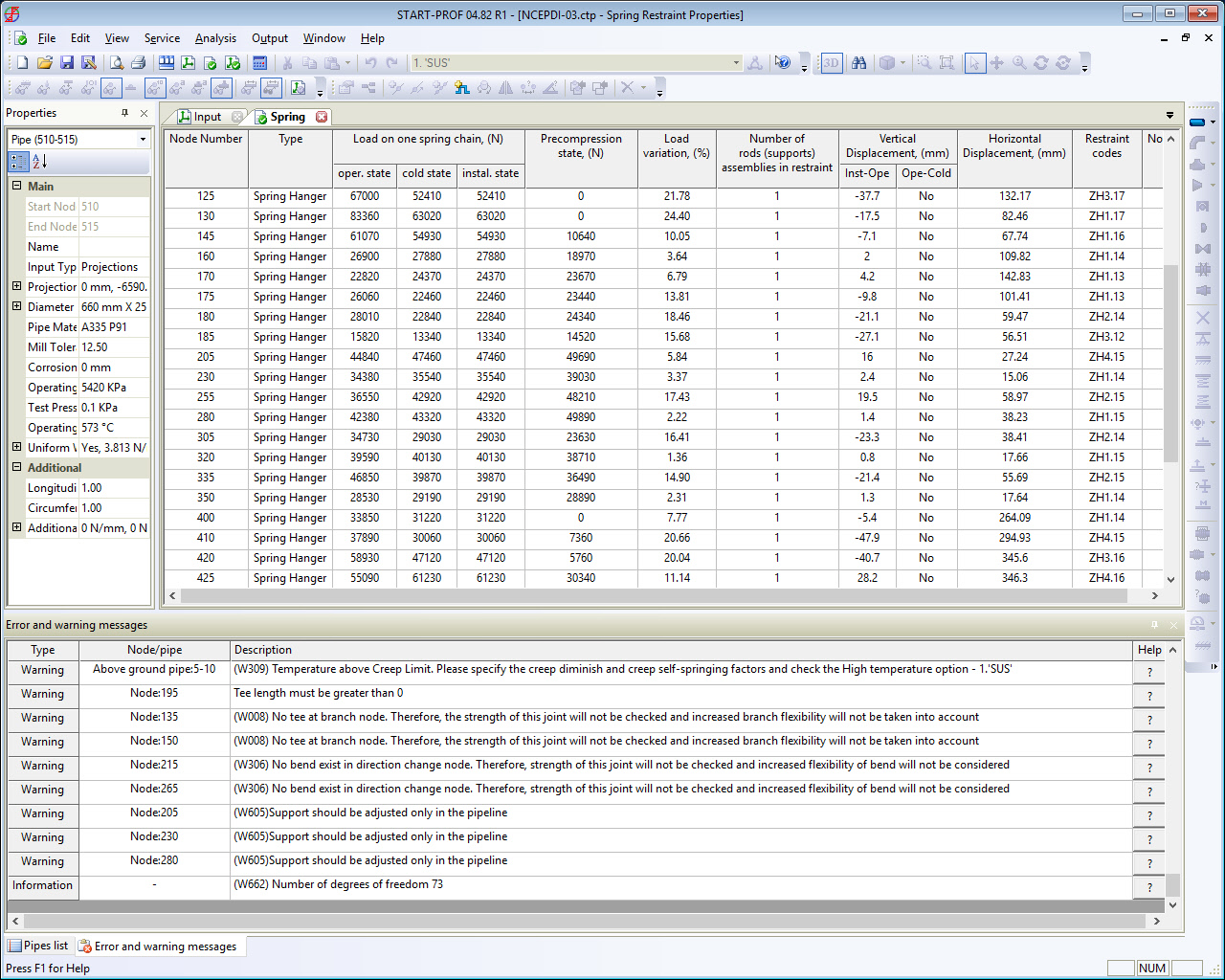

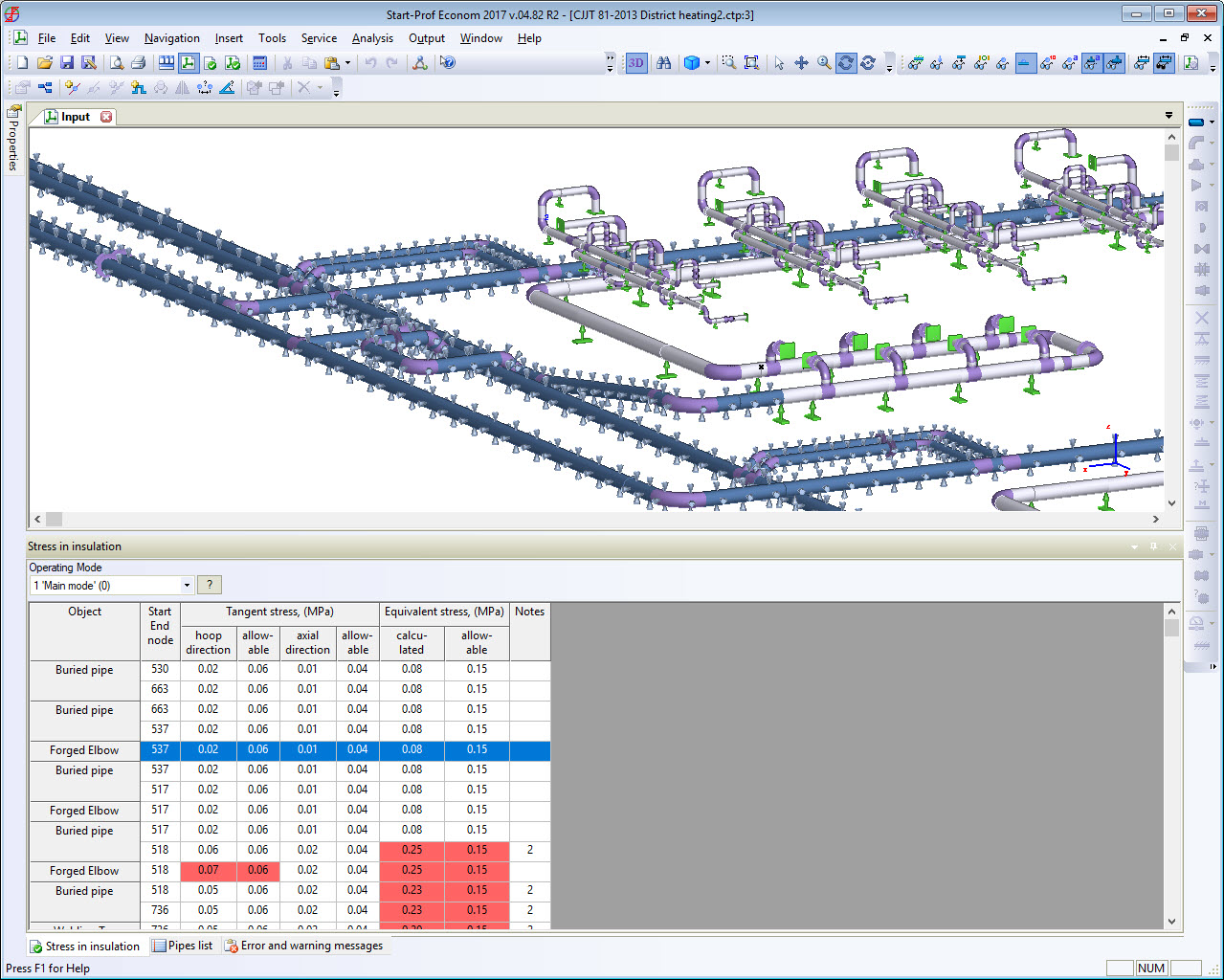

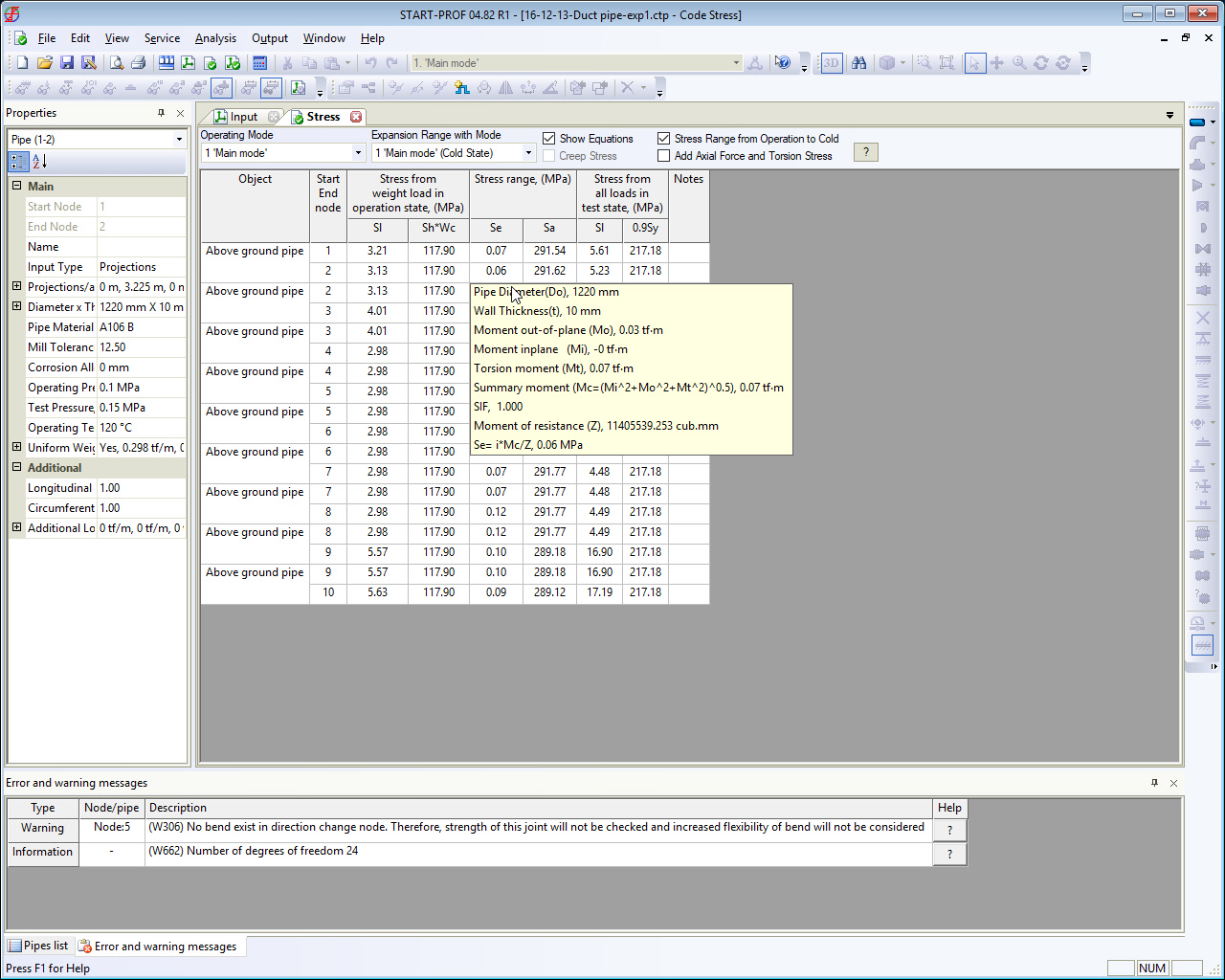

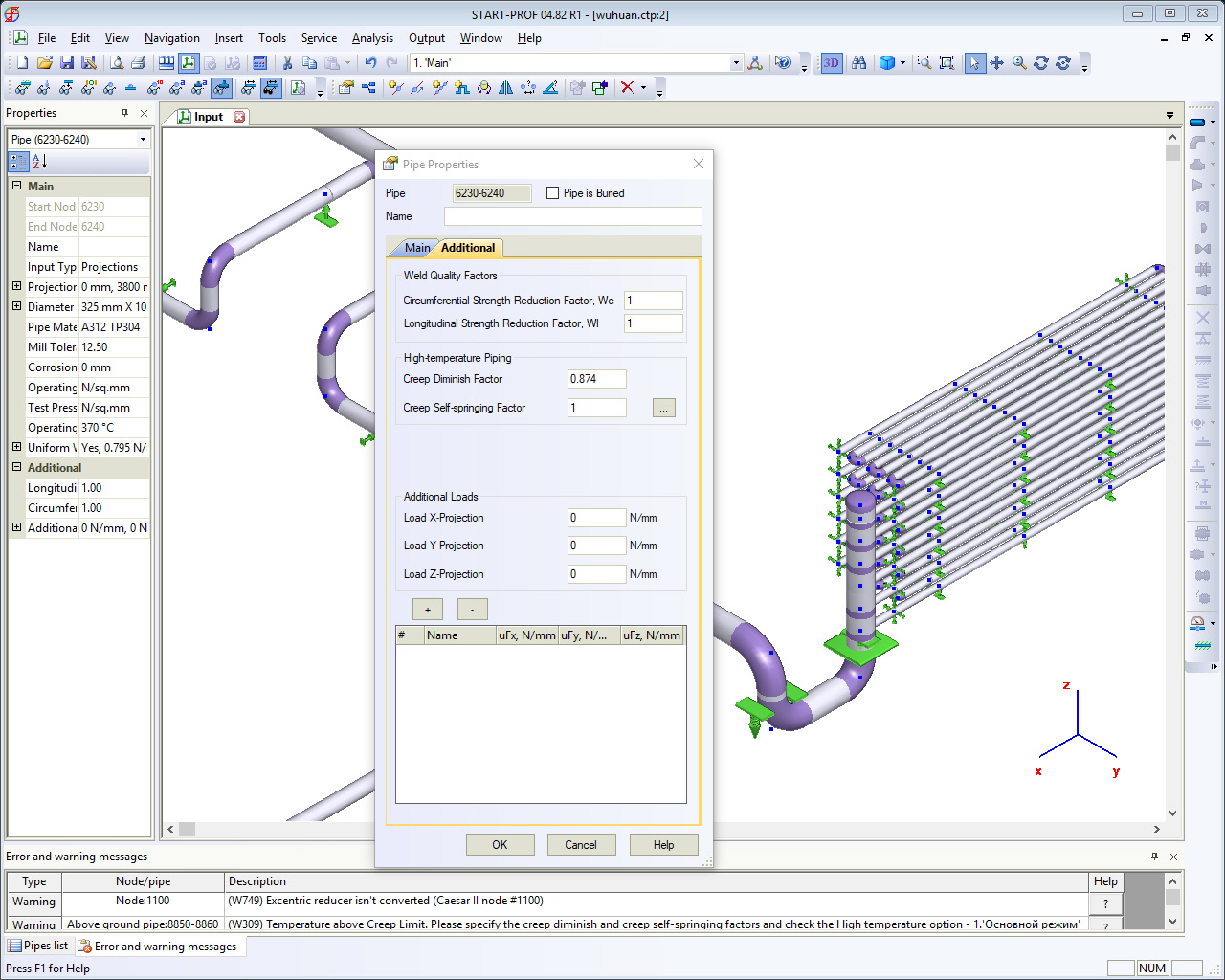

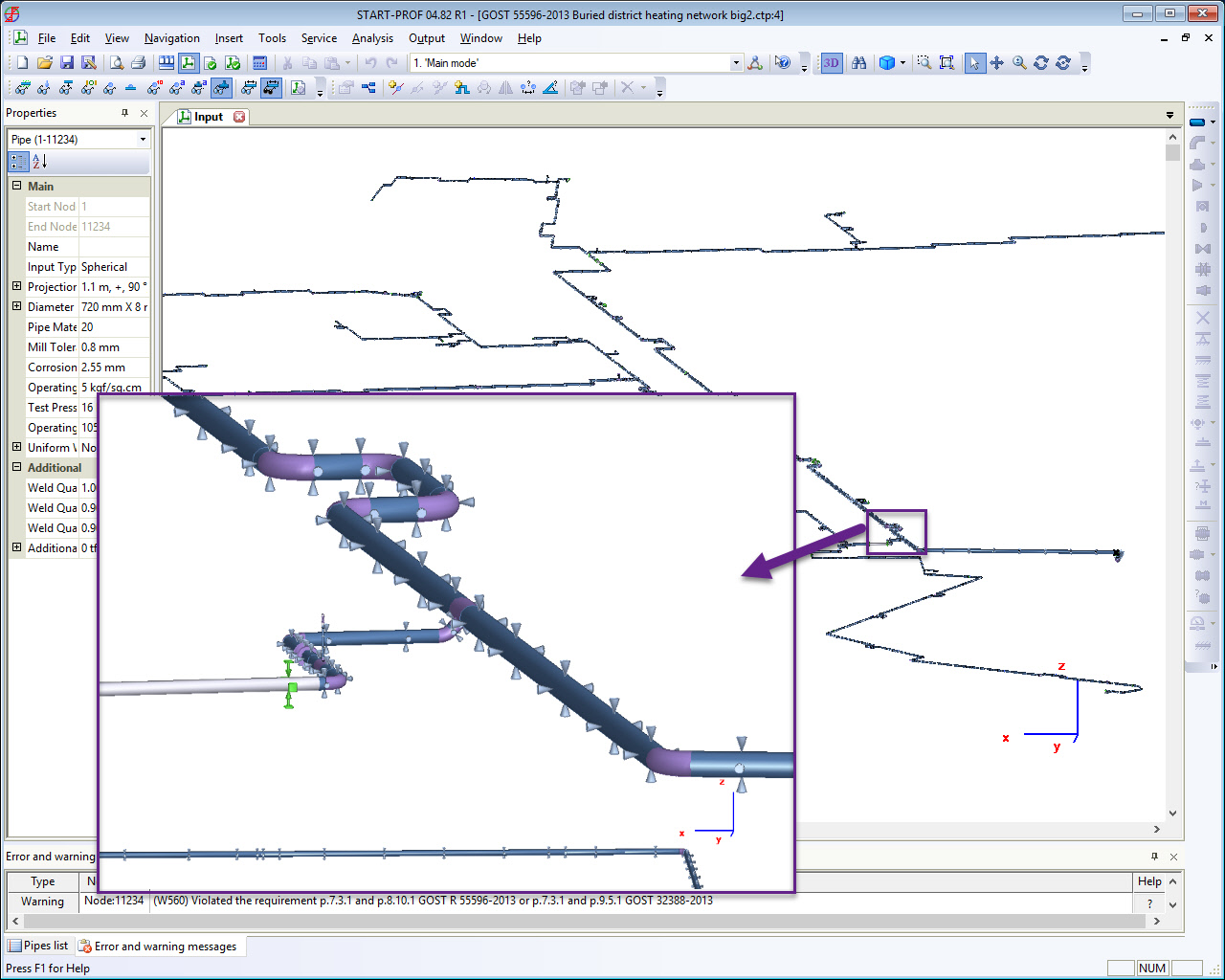

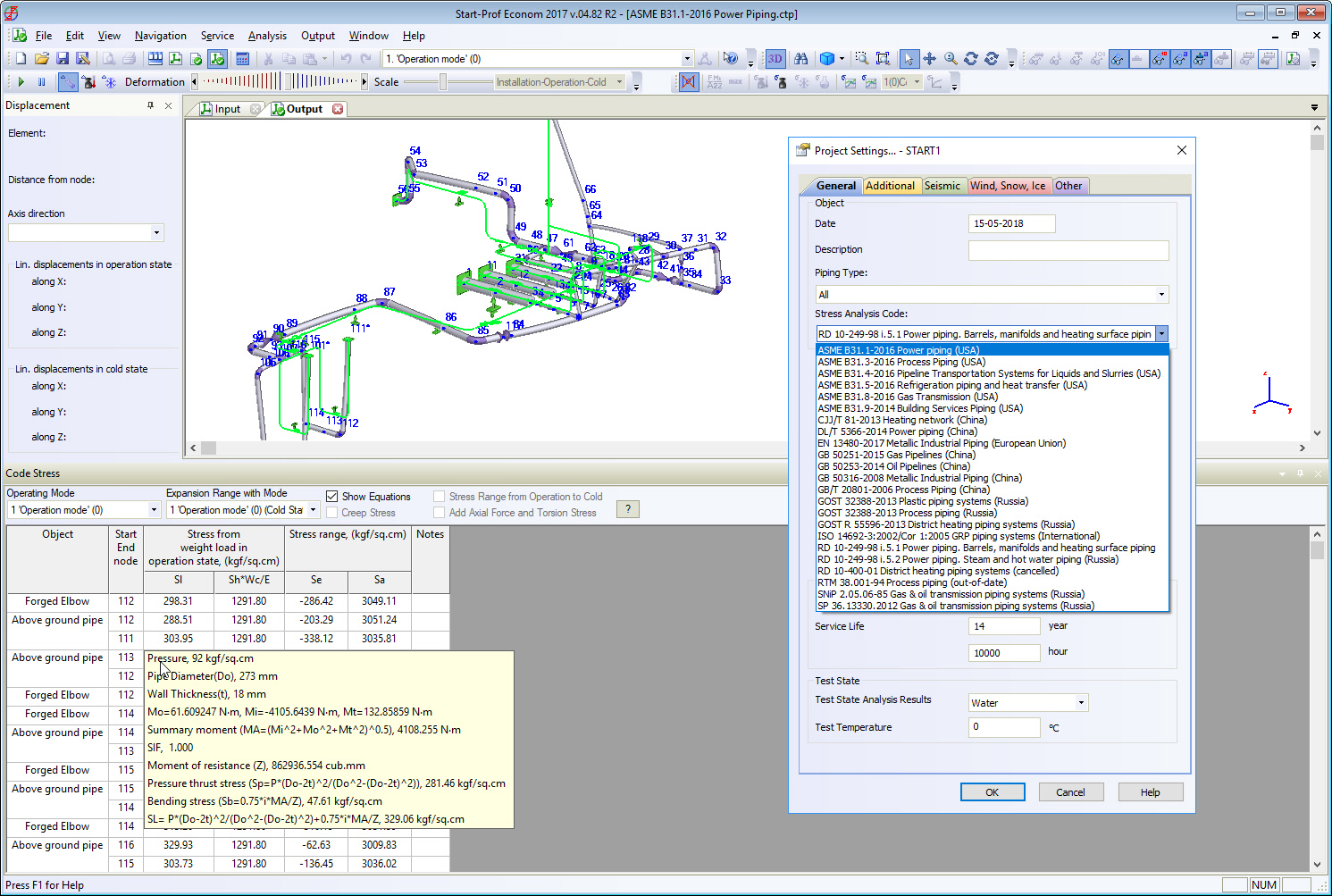

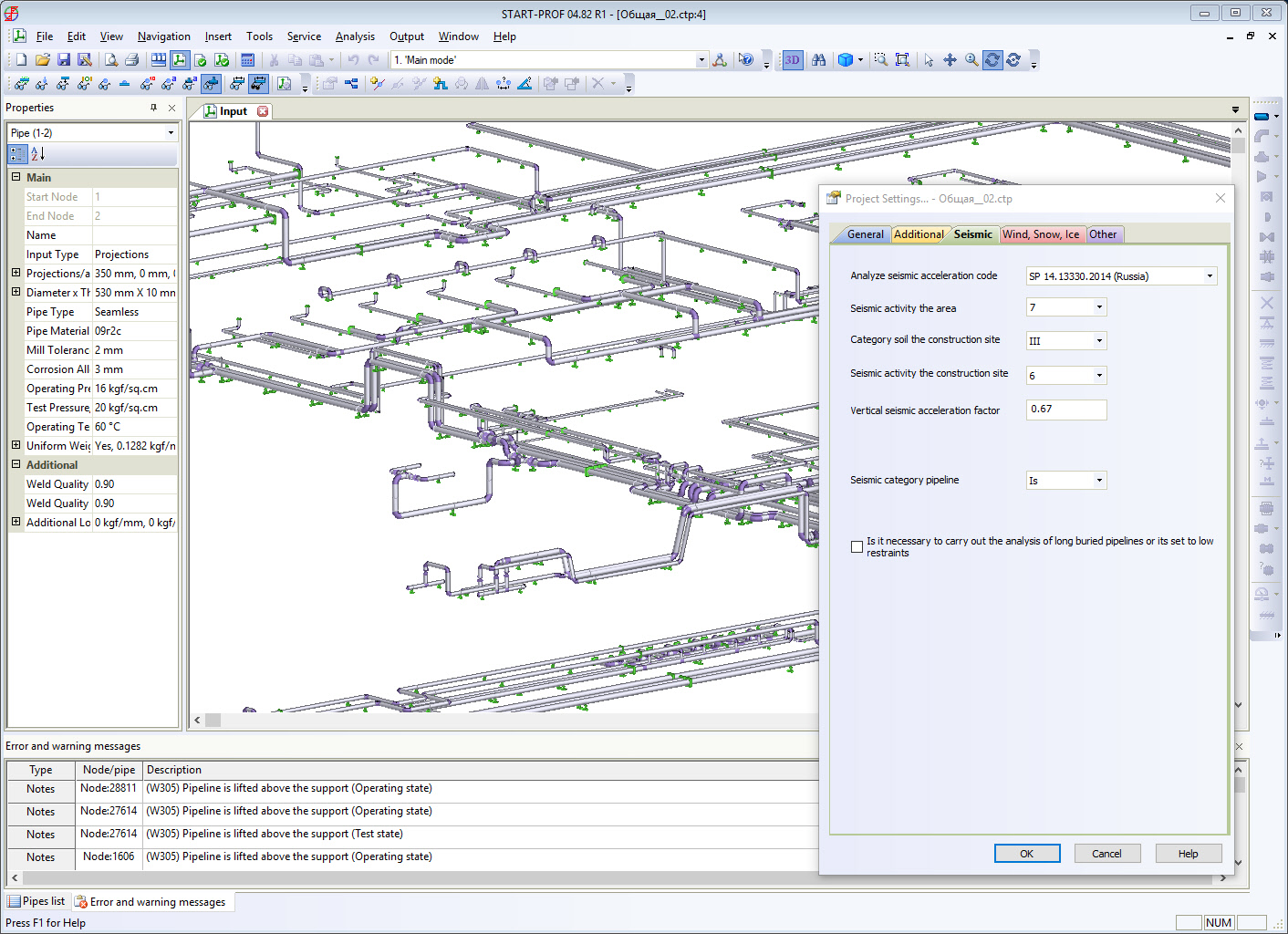

PASS/START-PROF is so smart that you need just draw the piping like in 3D modeling software and push the button "run analysis". PASS/START-PROF user should think about piping design, not about node numbering, model creation, etc. PASS/START-PROF will tell you if your model has any problems and show where exactly. All checks are made automatically: stresses, support loads, expansion joint deformations, flange leakage, buckling, loads on springs in all operating modes, stresses in insulation, and stresses in flaws. Table cells with a problem are marked with a red color. All results can be presented in any coordinate system: global, local. PASS/START-PROF offers detailed pipe stress report with all equations that was used; you can check all equations manually.

Enabling new users to perform piping systems analysis of any size or complexity in days rather than months.

Process and piping engineers of more than 3,000 companies in many countries already use the software every day for stress analysis and design of different types of pipelines.

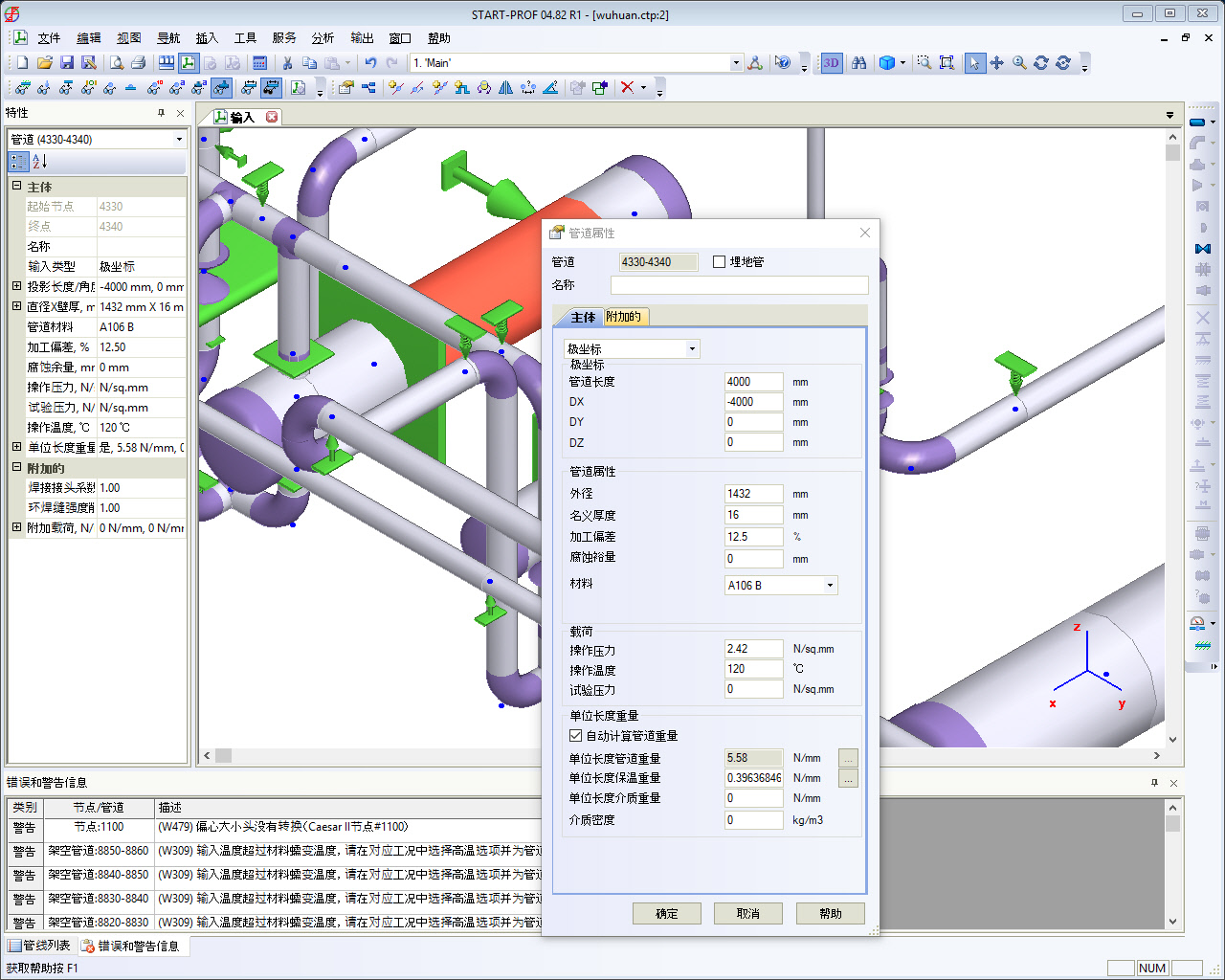

PASS/START-PROF has a smart, intuitive and friendly user interface and user's manual in English, Chinese, and Russian languages.

In PASS/START-PROF everything is simple and straightforward, since you are working with modern object model. You can compose your piping using objects like pipe, bend, tee, reducer, cap, expansion joint, restraint, valve, flange, and other like in 3D modeling software. You don't have to bother with node numbering at all; you can modify your model at any moment using copying, rotating, mirroring, node renumbering, cut, copy, paste any part of the model, add nodes, delete nodes.

To use ASME B31J in PASS/START-PROF you can just turn on the option "ASME B31J". To model buried pipelines just select that pipe is buried. No need to convert whole model using other software.

PASS/START-PROF is successfully used in many industries:

- Power and District Heating

- Oil and Gas

- Process

- Chemistry

- Metallurgy

- Other Industries

Reduces Analysis Time, Effort, and Cost

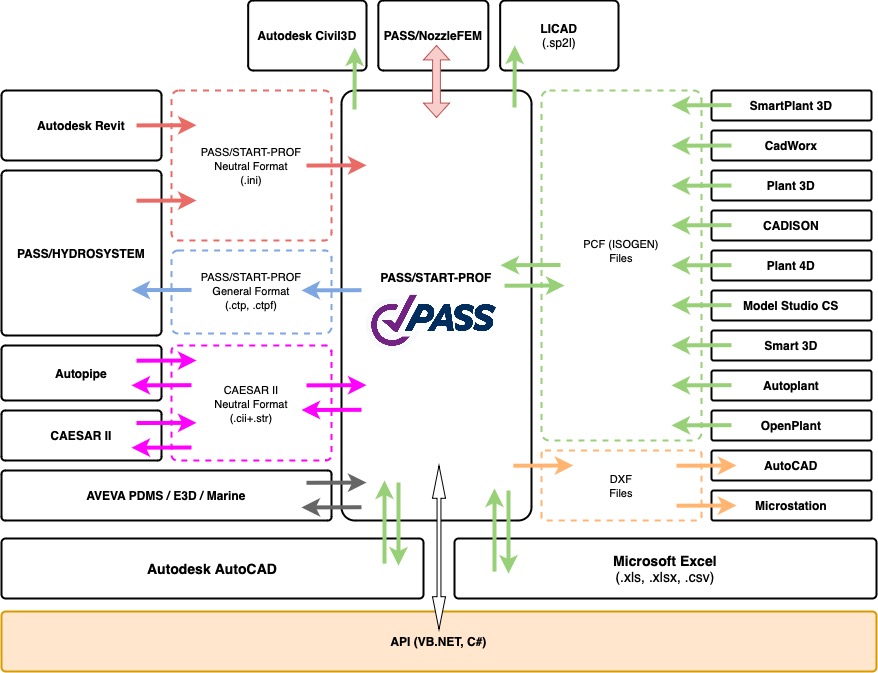

PASS/START-PROF can import piping models ready for analysis from CADWorx, SmartPlant 3D, AVEVA PDMS, AVEVA E3D, Autodesk REVIT, Bentley Autopipe, HEXAGON CAESAR II, OpenPlant, Autoplant, Smart 3D, etc. You can modify your model without any problem after import.

PASS/START-PROF is an ideal component for integration into any piping design workflow with interfaces to multiple design and analysis software tools.

PASS/START-PROF offers quick 1st hand support from developers and from experienced piping engineers in UK, China, Mexico, Brazil, Australia, Egypt, Turkey and other countries. Support response speed and quality is guaranteed and can be offered on regional language. User feedback is accepted and used to improve development of PASS/START-PROF.

Features and Advantages

Reliable software with a long history

PASS/START-PROF will save you time and money

User friendly interface

Context-sensitive help system and detailed user manual

Integration with FEA

PASS/START-PROF and PASS/NOZZLE-FEM is free integration module that allows to use the finite element method analysis with shell elements to calculate the stress intensification factor (SIF) and flexibility k-factors, allowable loads on nozzles and analyze stresses in critical elements using FEA. Using this module allows to overcome the application limits of code and calculate the SIF, k, and allowable loads more accurately and less conservative which save the metal volume and reduce the piping cost.

See Knowledge BaseMicrosoft Word report generator

Allows you to export input data and tables of calculation results to Microsoft Word custom templates.

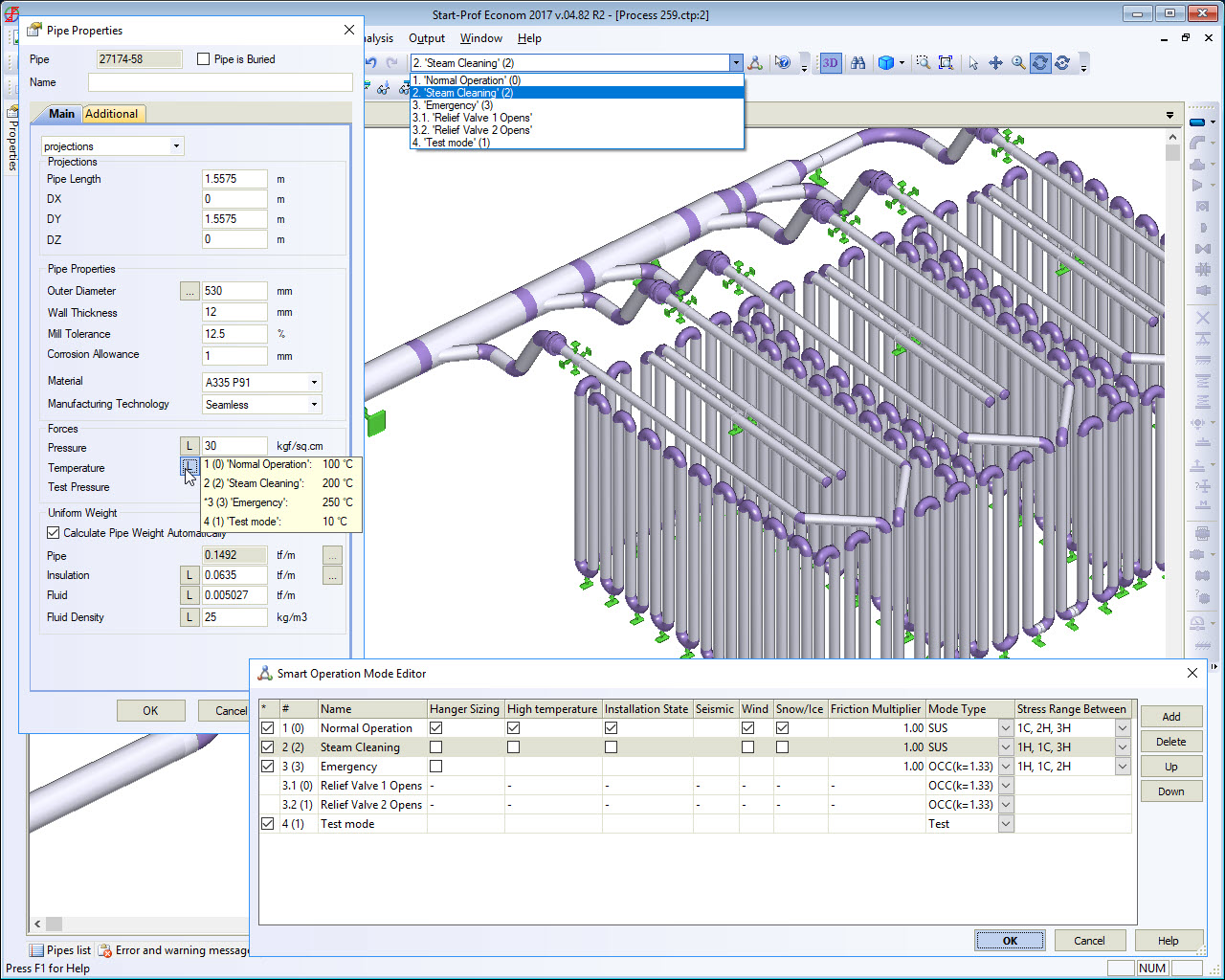

See Knowledge BaseOperation Mode Editor

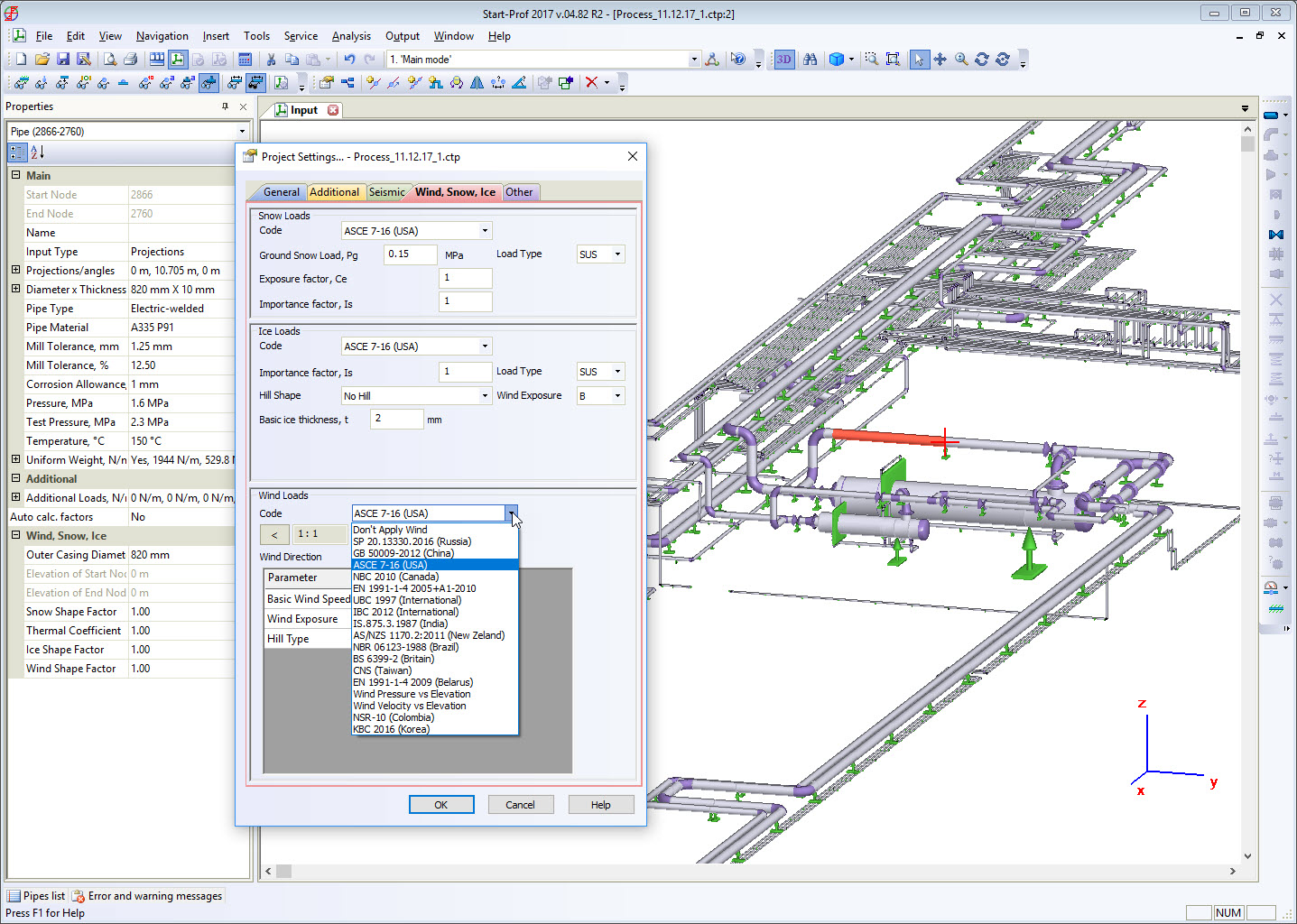

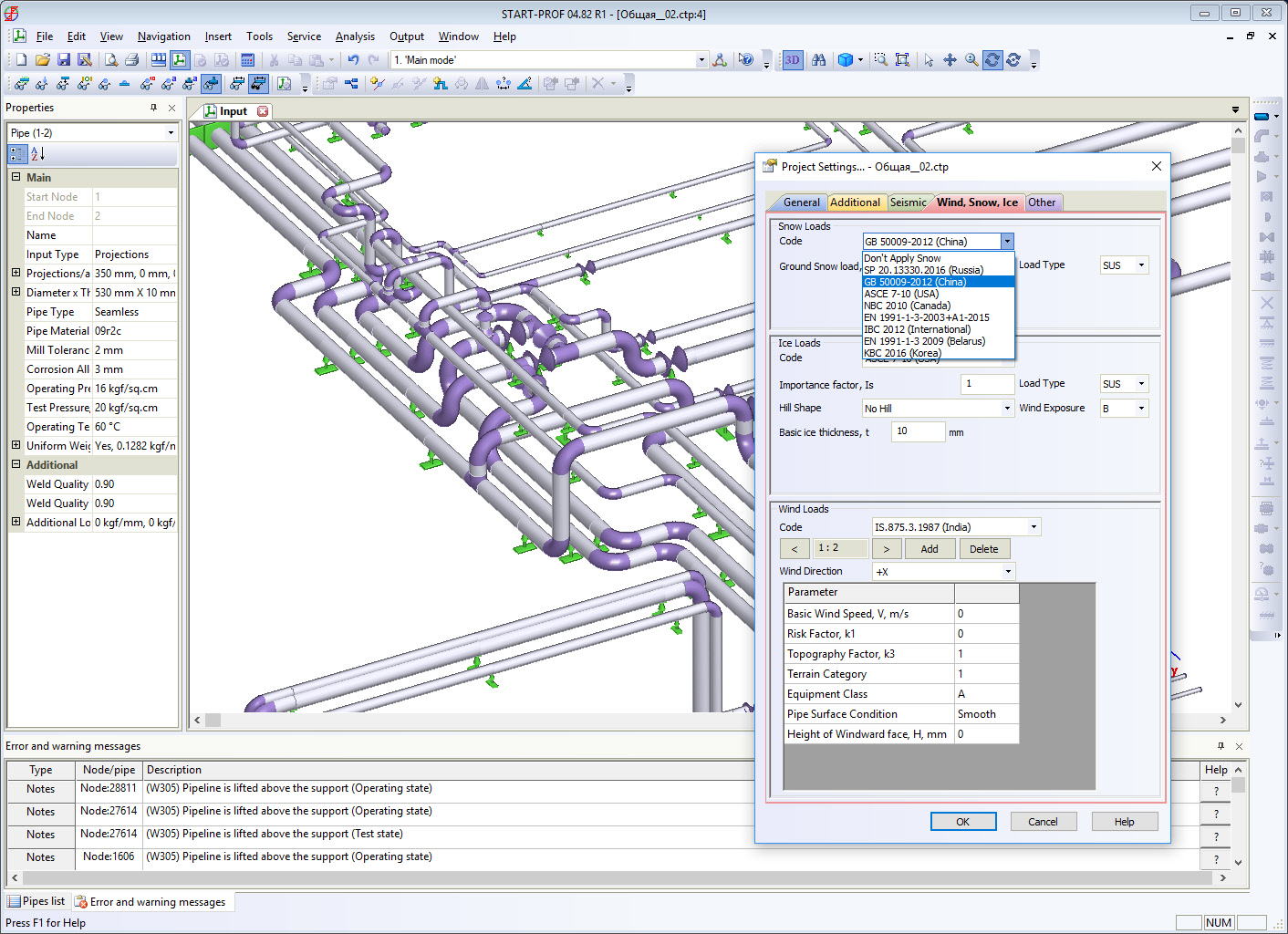

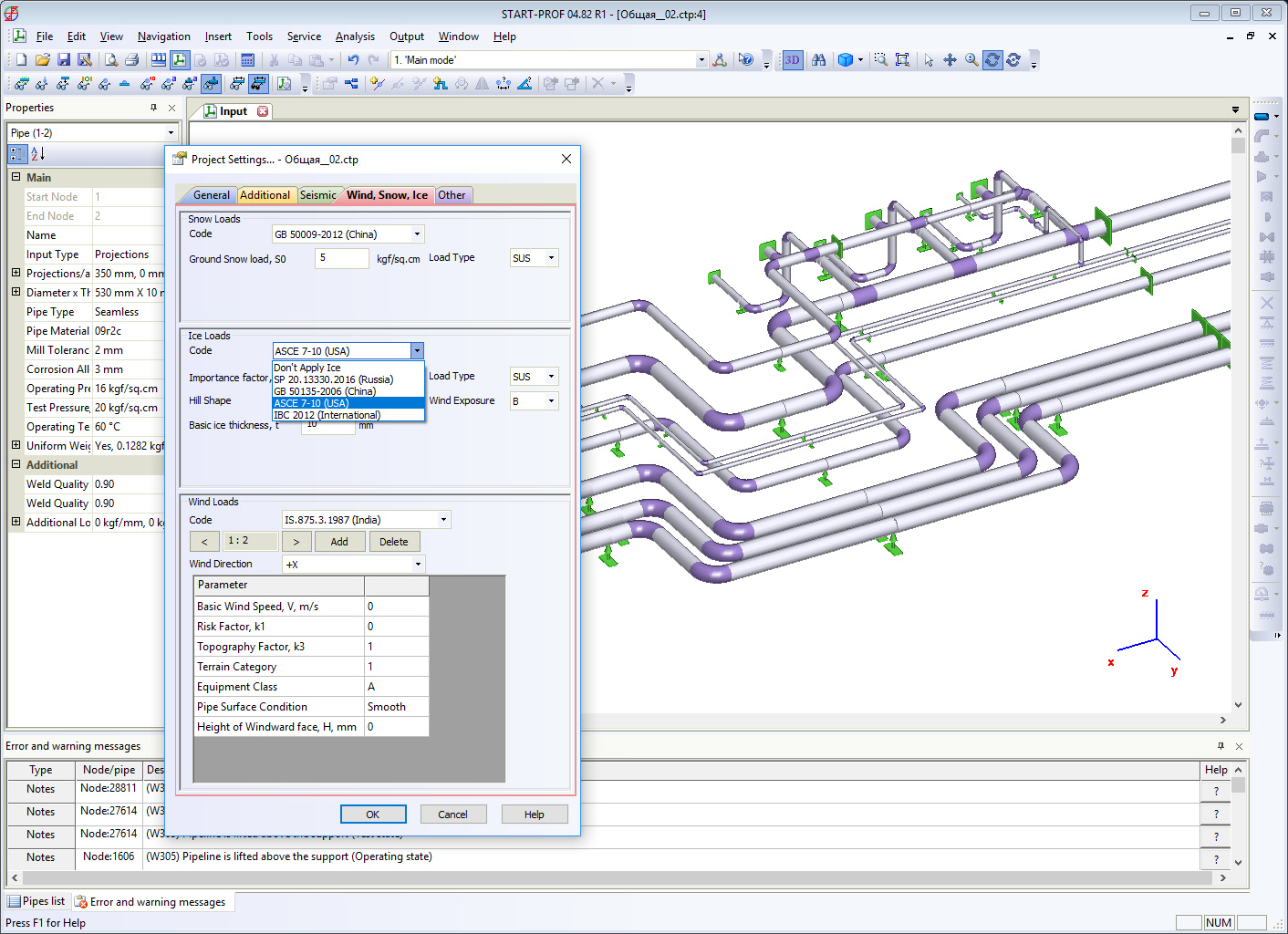

The Smart Operation Mode Editor allows users to just draw the piping, add general snow, wind, ice, as well as seismic load information and run the analysis. All appropriate load values and load cases will be created automatically according to selected codes. Time consuming manual creation of load cases is no longer needed. Smart Operation Mode Editor allow you to analyze several operation modes of piping in one project file. For each operation mode the special template load cases automatically generated.

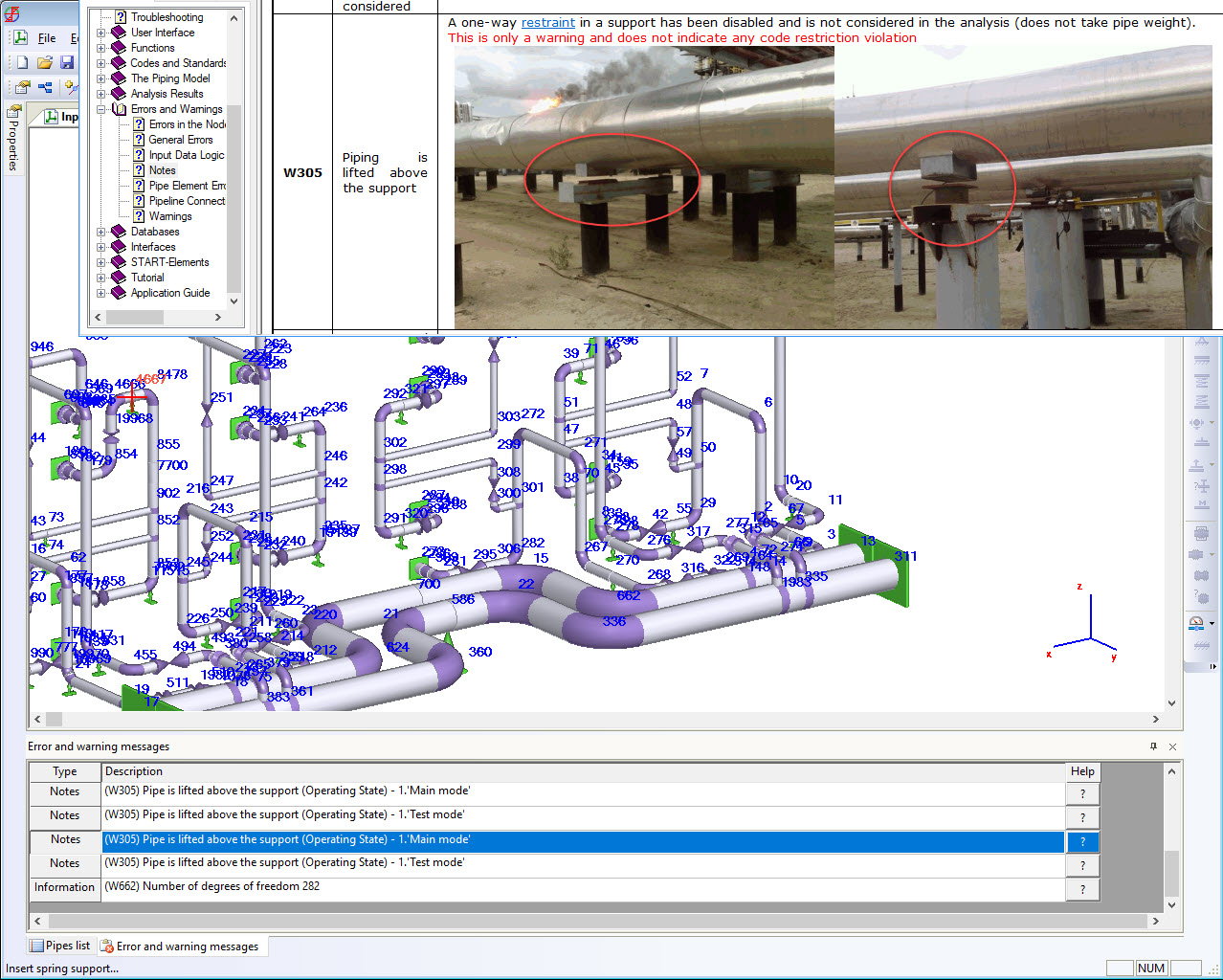

The Smart Warning Message Window

The Smart Warning Message Window warns about e.g., pipe lifting off, overloading of supports and springs, or excess of deformations of expansion joints. Important problems in the model will not be missed.

See Knowledge BaseSmart interactive reports

Analysis results are presented in smart reports including:

- Code Stress Report

- Support Loads Report

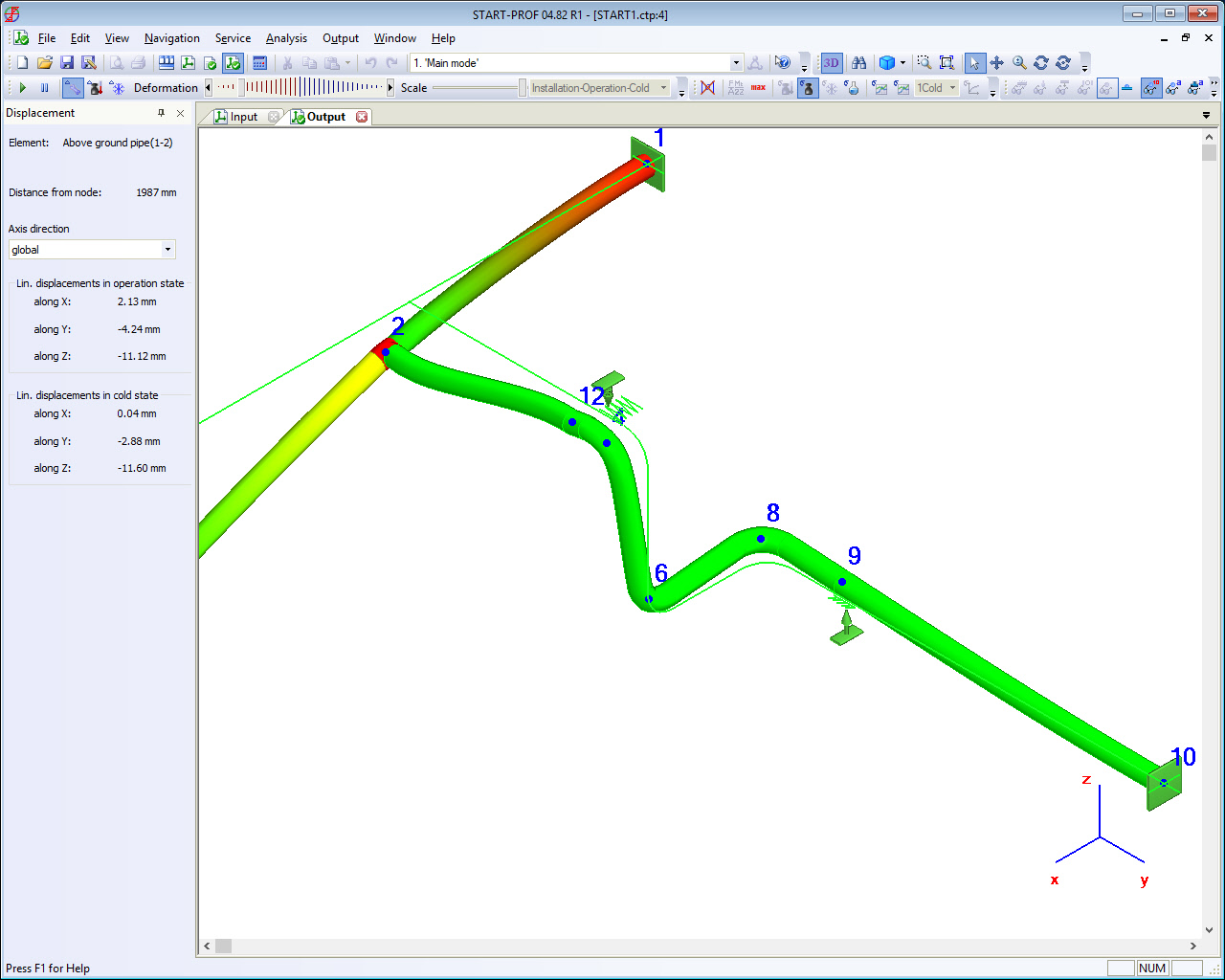

- Displacements Report

- Variable Springs Selection Report

- Constant Springs Selection Report

- Expansion Joints Report

- Flanges Leakage Report

- Pipes and Fittings Wall Stability Report

- Internal Forces Report

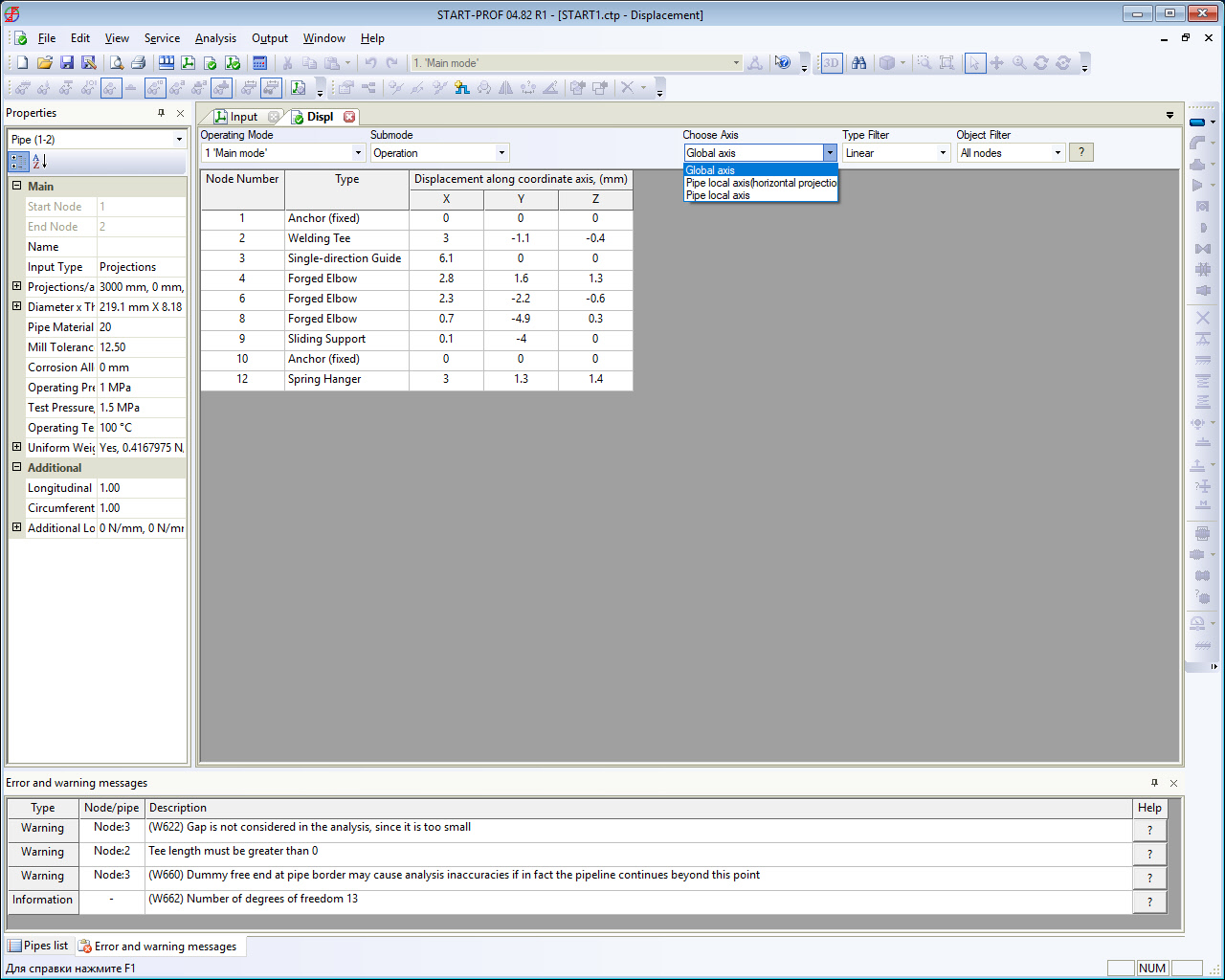

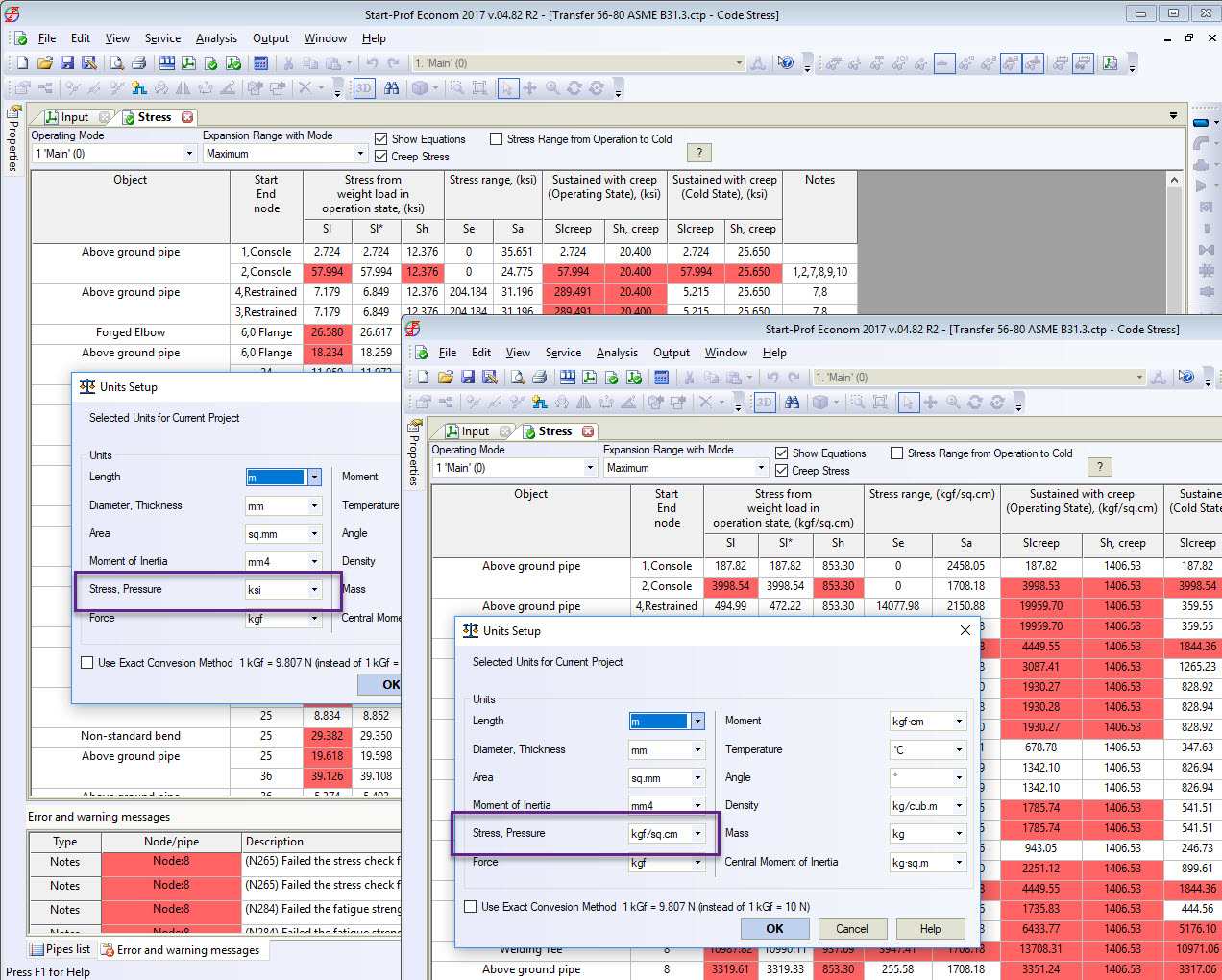

All reports are interactive to make understanding of the analysis results quicker and easier. You can select operating mode, coordinate system, add filters, or sort data on-the-fly.

See Knowledge BaseWorking With Independent Piping Segments

Several disconnected and independent piping segments can be created in one file

See Knowledge BaseResults can be analyzed using interactive 3D graphics where you can see deformed shape animation in different operating modes, such as stress color maps.

Analysis Results are presented in interactive tables of stress, loads, displacements, expansion joint deformations, wall stability analysis, or internal forces. You can select operating mode, coordinate system, filter data, or sort data on-the-fly.

See Knowledge BaseUnits can be changed very quickly

Automatic on-the-fly checking of all pipes and fittings wall thickness for pressure load

See Knowledge Base

PSRE proprietary method for solution of nonlinear model with friction converges in most cases

See Knowledge Base

Equipment Nozzle Flexibility

See Knowledge Base

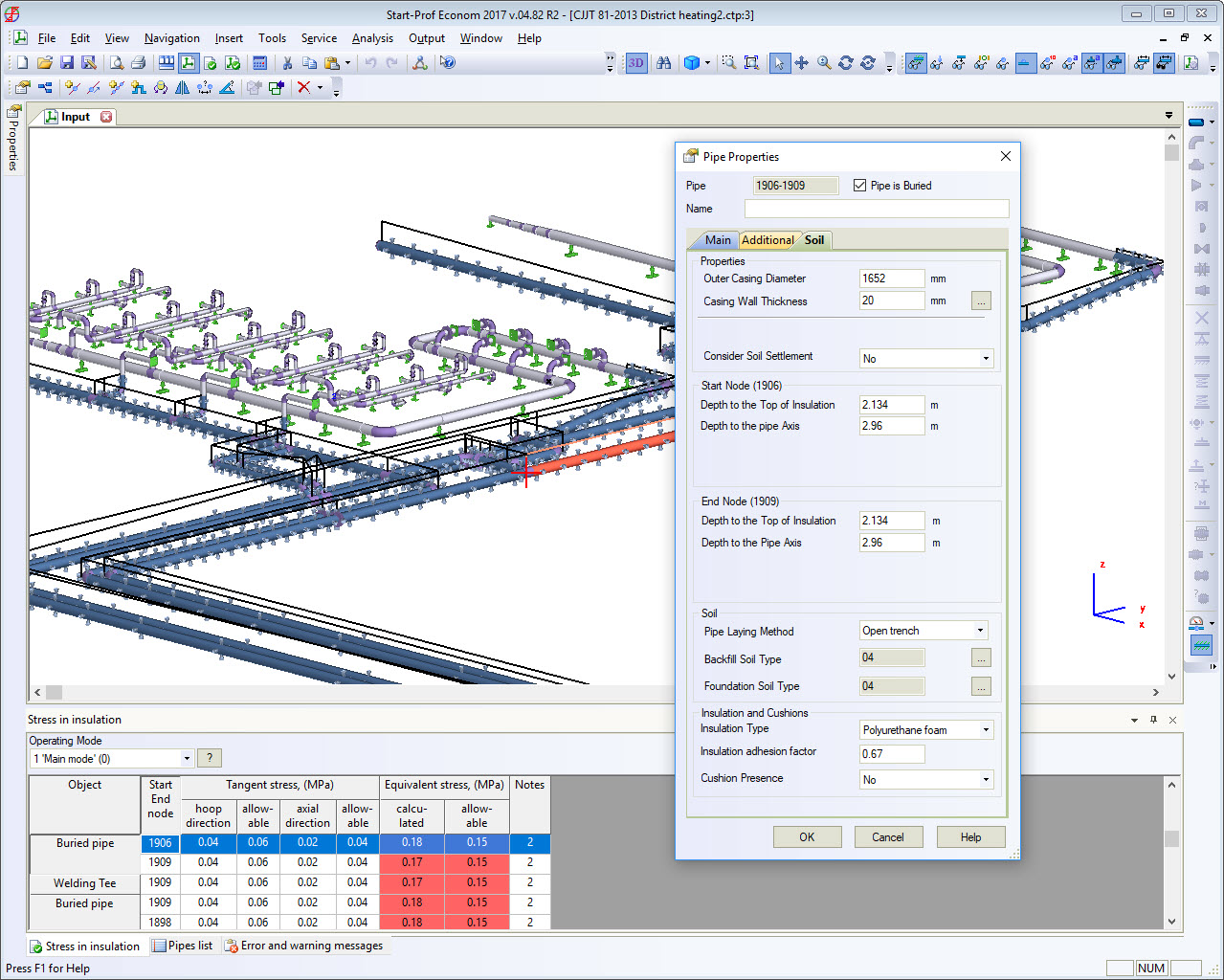

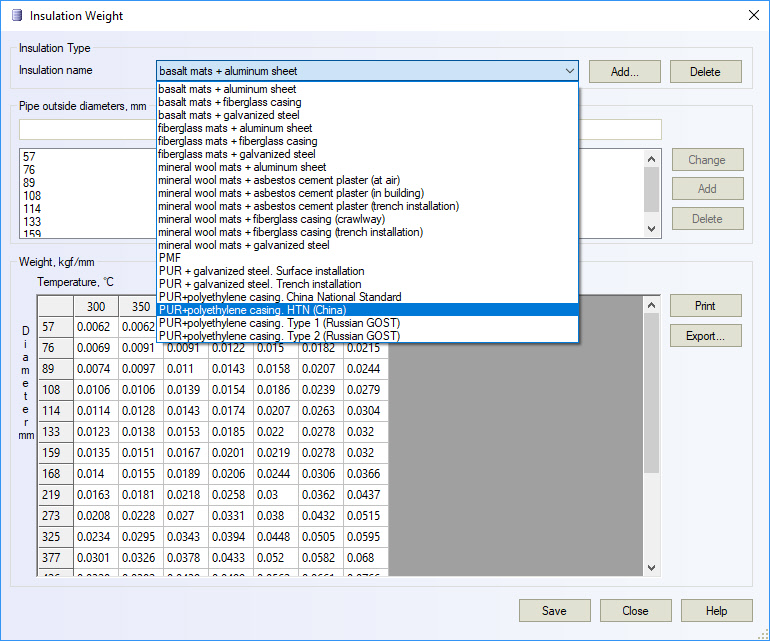

PUR insulation stress check

PASS/START-PROF can check stresses in PUR insulation.

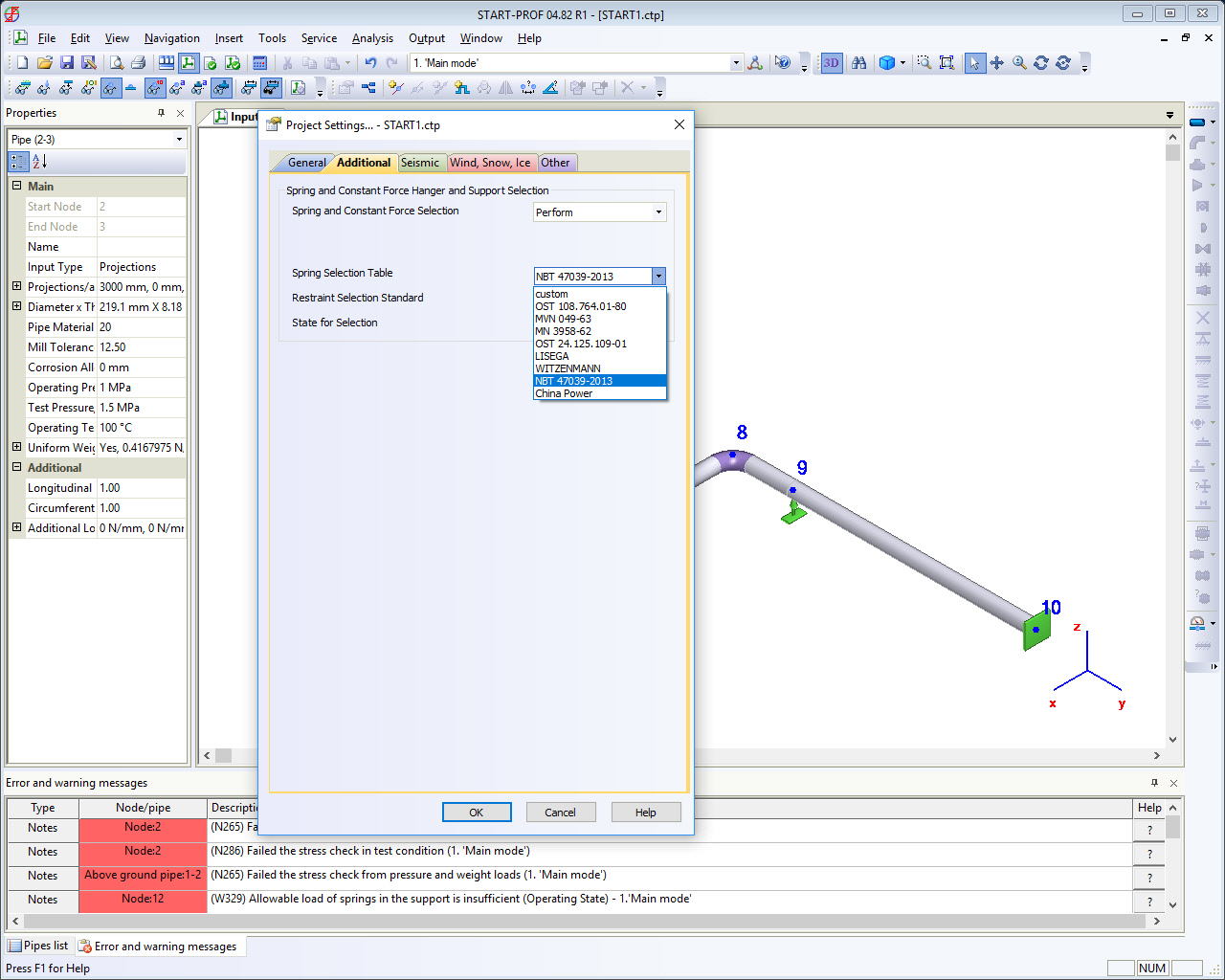

See Knowledge BaseAutomatic spring hanger and support selection

PASS/START-PROF checks allowable load in all operating modes, not just only during support selection.

See Knowledge BaseAutomatic constant load hanger and support selection

See Knowledge Base

Translation and rotation Bourdon effect in pipes and bends

See Knowledge Base

PASS/START-PROF nonlinear effects: friction in sliding, guide and spring supports, rotational rods and hangers, single-directional restraints

PASS/START-PROF consider specific behavior of long-radius pipe bends

See Knowledge Base

Broad Applicability

Pipelines that can be analyzed include piping for: process and power, gas and oil transportation, district heating piping, hot water supply, and more. Stress, flexibility, stability, and fatigue strength analysis are performed for buried, above ground, vacuum, high pressure, high temperature, and cryogenic piping. Pipelines with various types of restraints, fittings, and expansion joints can be easily evaluated. PASS/STARTPROF also offers automatic selection of constant and variable spring supports.

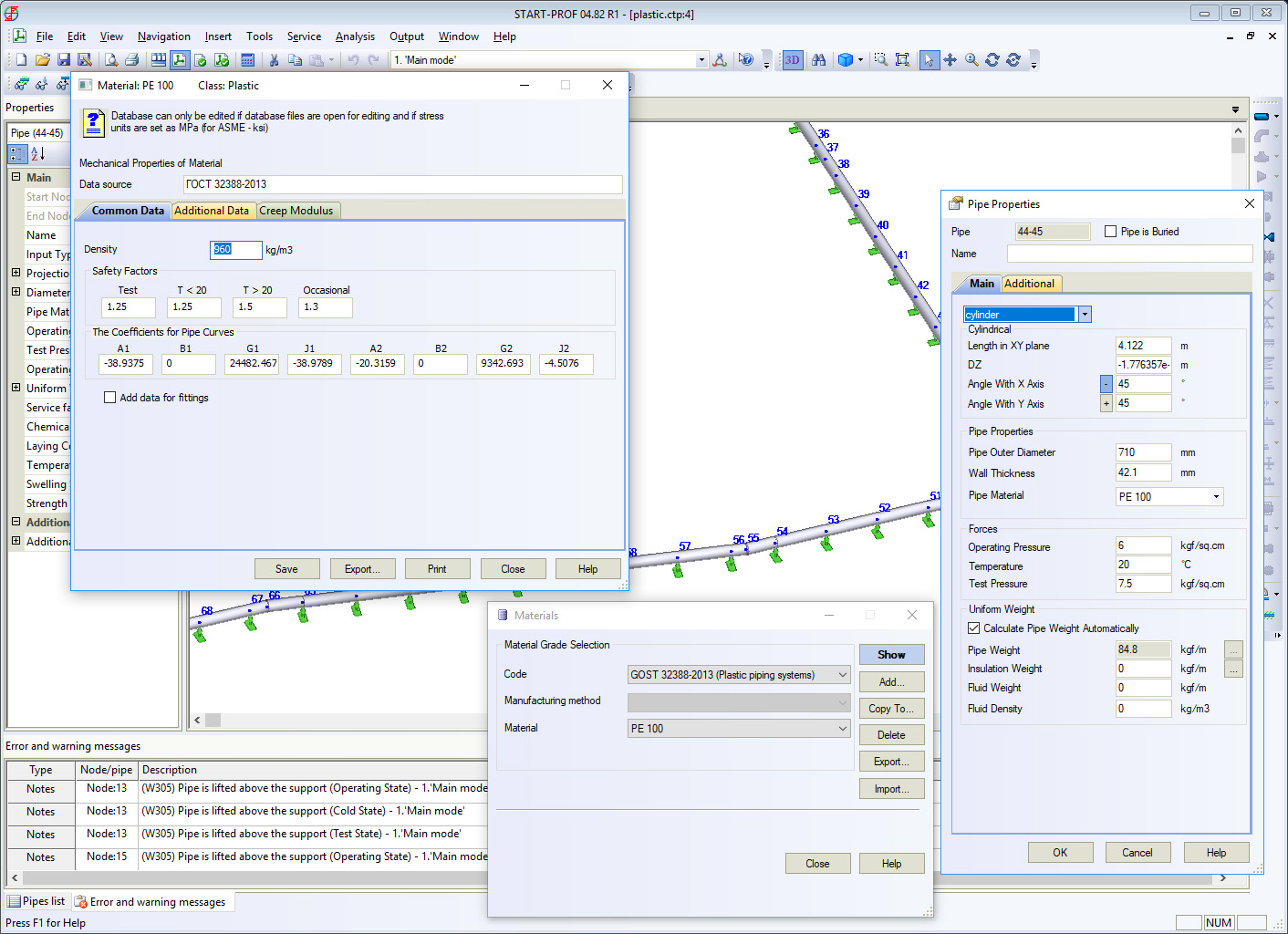

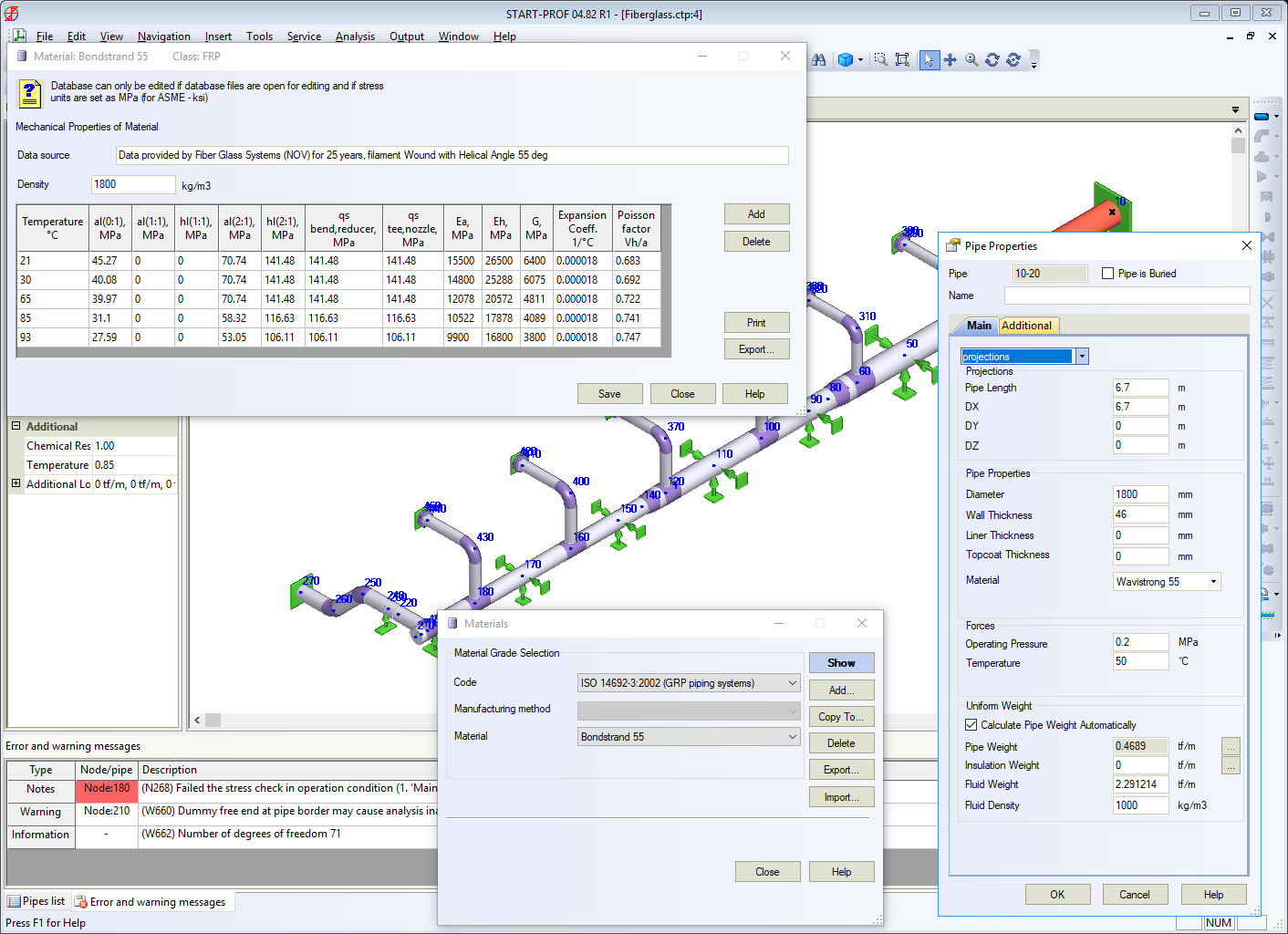

PASS/START-PROF can analyze a wide range of materials used in pipelines including: steel, nonferrous materials, plastic pipes and fittings, orthotropic materials such as fiberglass, reinforced plastic, glass reinforced plastics, and glass reinforced epoxy.

The following piping types are covered:

Above-ground Piping

See Knowledge Base

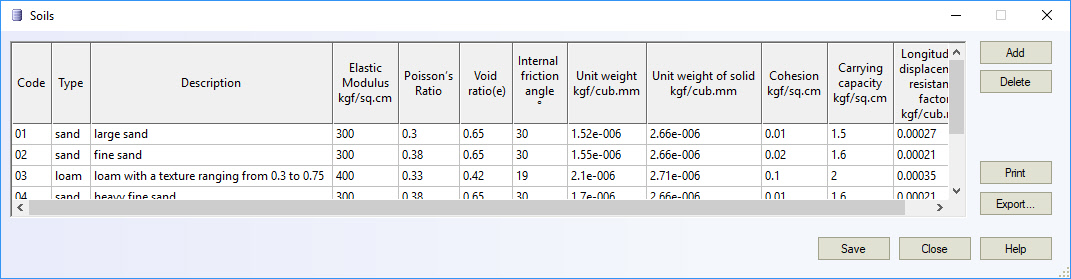

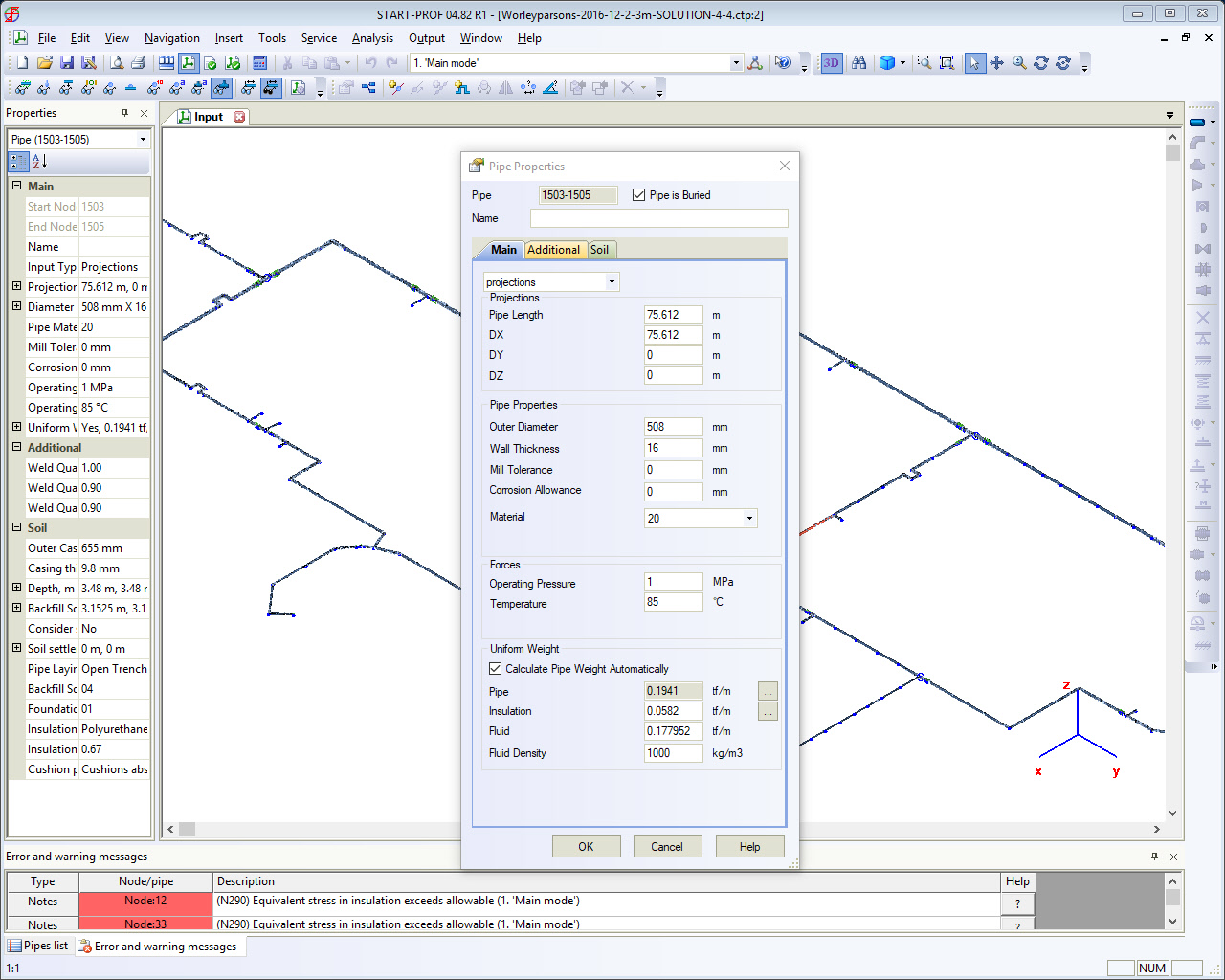

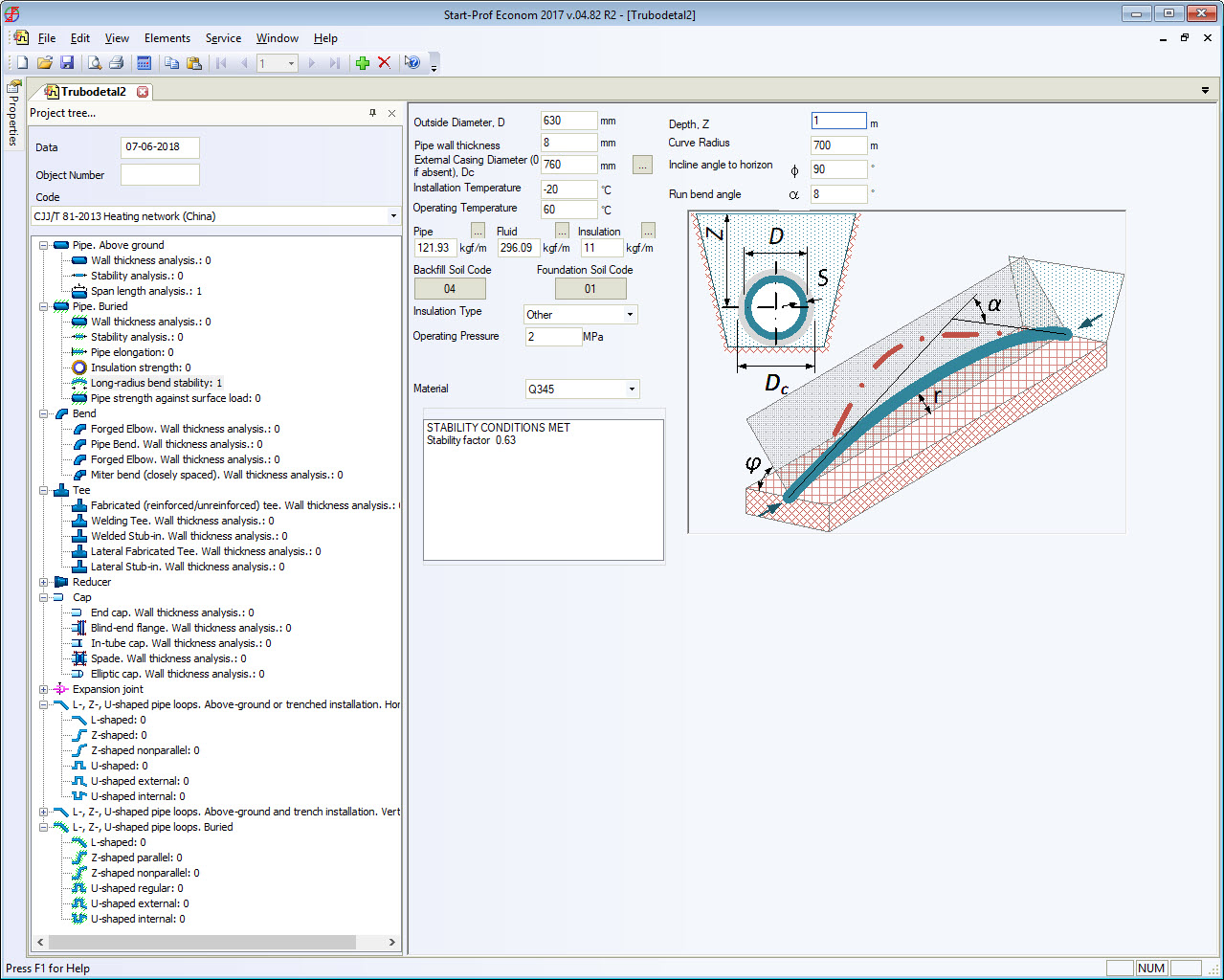

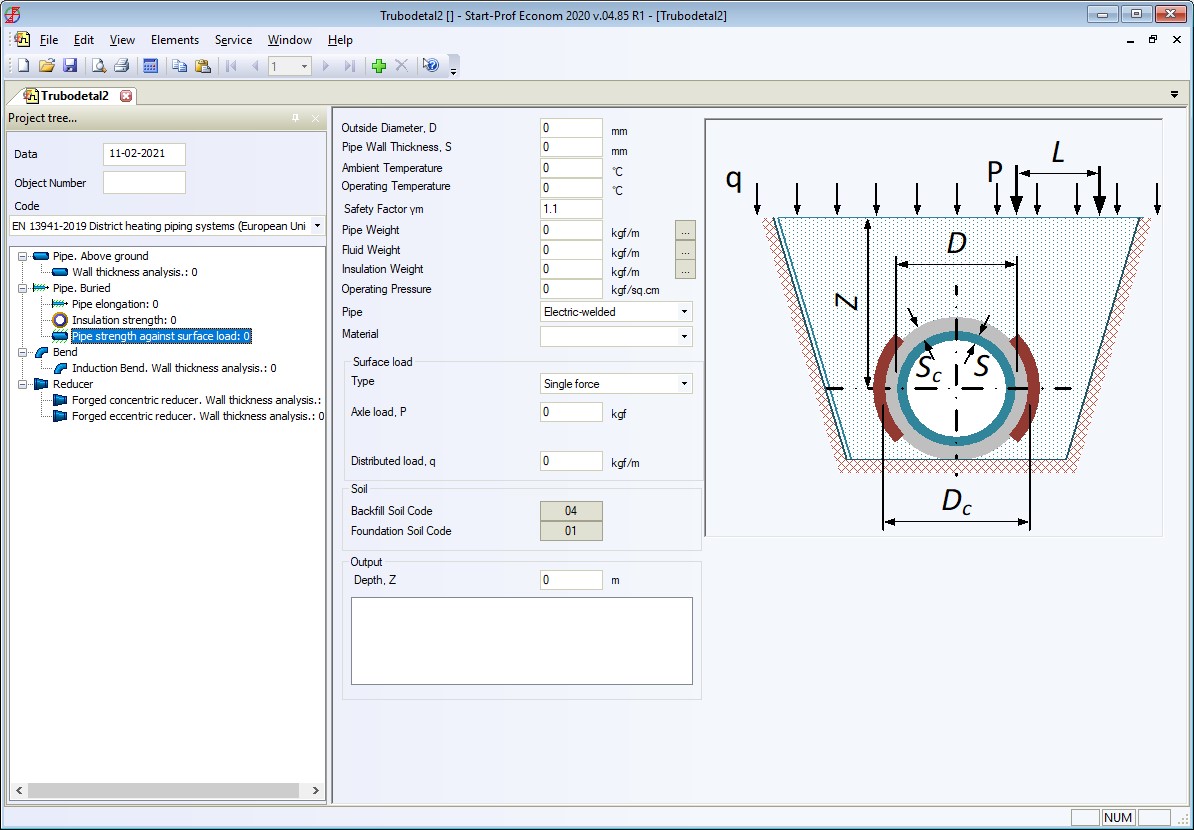

Buried Pipelines

PASS/START-PROF can model soil flexibility + PUR insulation layer flexibility + expansion cushion flexibility including soil settlement and swelling modeling, longitudinal stability analysis, buoyancy and flooded soil. The user can simply specify soil type from database, and define the pipe depth to run the analysis without having to specify restrained and unrestrained zones, calculate the virtual anchor length, nor run a soil modeler. PASS/START-PROF will automatically do what is required for the correct soil simulation. PSRE has several years of experience modeling buried piping for District Heating and other applications.

See Knowledge BasePUR Insulation Stress Check

PASS/START-PROF can check stresses in PUR-Insulation.

See Knowledge BaseVacuum Piping

Vacuum piping wall stability check considering stiffening rings reinforcement is performed.

See Knowledge BaseJacketed Piping

See Knowledge Base

Cryogenic Low Temperature Piping

High Pressure Piping

High Temperature Piping with Creep and Stress Relaxation Effects

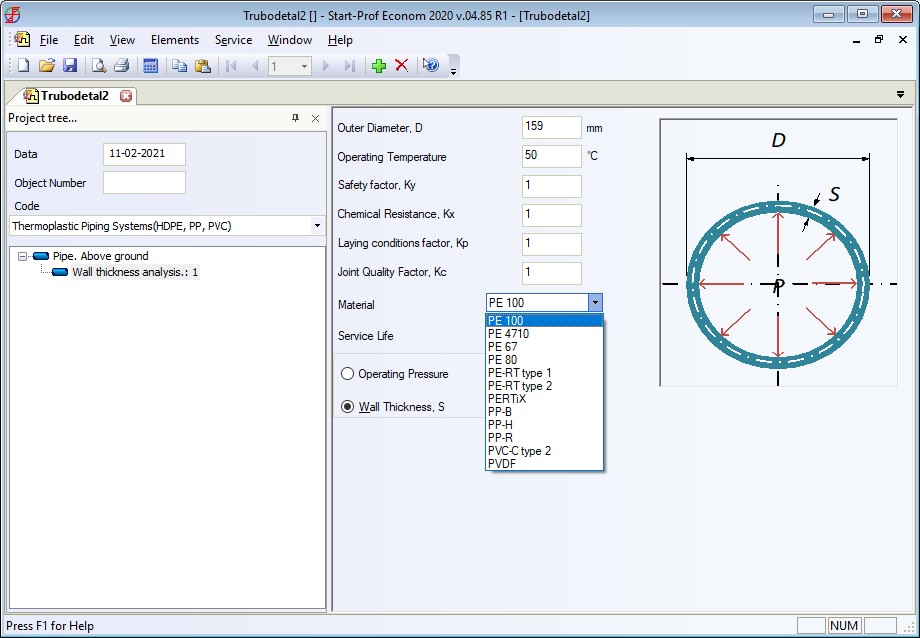

Plastic Piping

Easy to use plastic piping analysis for polyethylene (PE), polypropylene (PP), polybutene (PB), Polyvinylidene fluoride (PVDF), polyvinylchloride (PVC) etc. according to DVS 2205/DVS 2210 is provided. Above-ground and buried plastic piping can be analyzed, including PUR insulation layer.

See Knowledge BaseFRP, GRP Piping

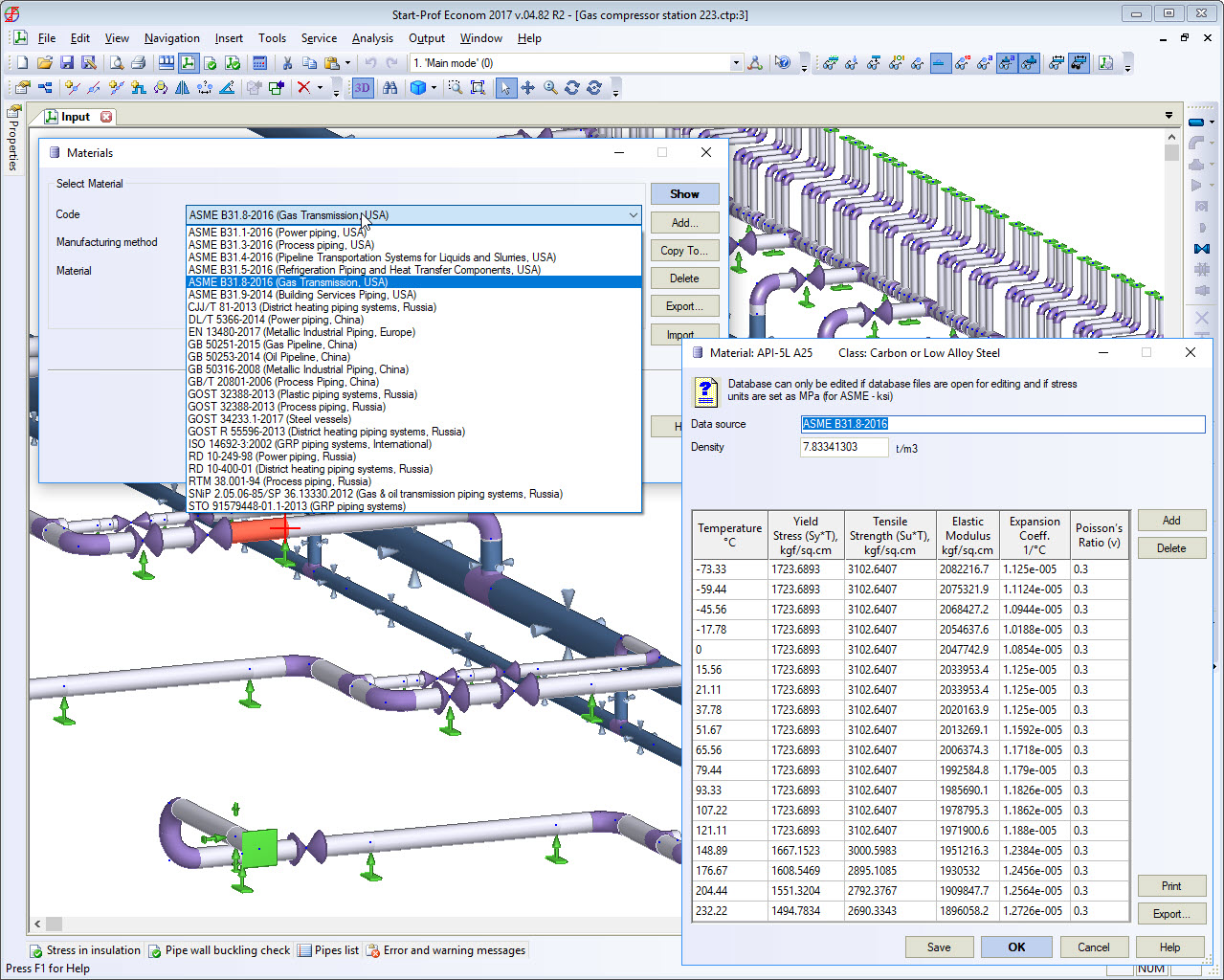

Databases

PASS/START-PROF include following databases:

Materials

Contains the physical properties of pipe and fitting materials. Each piping code has own database section. Due to this, plastic piping, fiberglass (FRP, GRP) piping can be calculated as easy as steel piping. You just select preferred material from database.

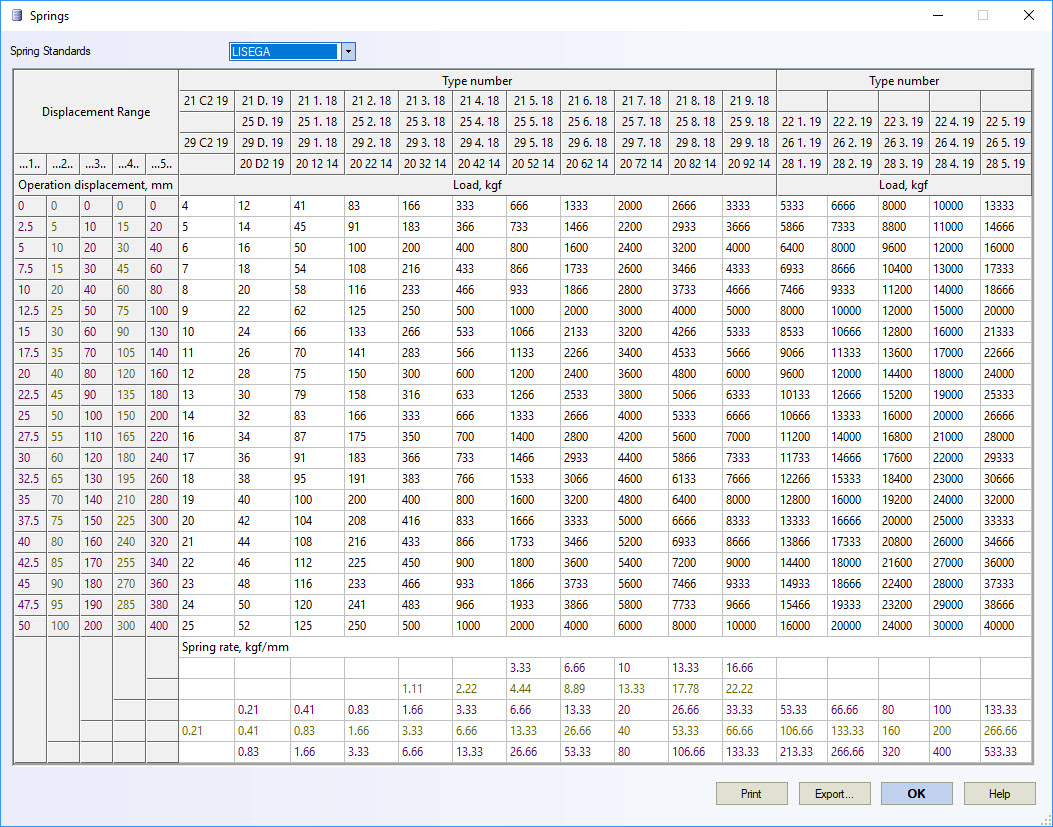

See Knowledge BaseVariable Springs

Contains variable spring support and hanger properties used for spring selection by the following manufacturers and codes:

- ANVIL

- LISEGA

- WITZENMANN

- NB/T 47039-2013

- China Power

- SEONGHWA

- Pipe Supports Ltd

- Carpenter & Paterson

- Gradior

- Pihasa

- Pipe Support Systems GmbH (PSSI)

- Piping Technology and Products Inc. (PT&P)

- Sarathi

- OST 108.764.01-80

- OST 24.125.109-01

- MVN 049-63

Constant Load Springs

Contains constant load spring hangers and supports properties used for selection by the following manufacturers and codes:

- ANVIL

- WITZENMANN

- Pipe Supports Ltd

- Carpenter & Paterson

- SEONGHWA

- NB/T 47038-2013

Soils

Contains soil properties that are used for buried pipeline modeling

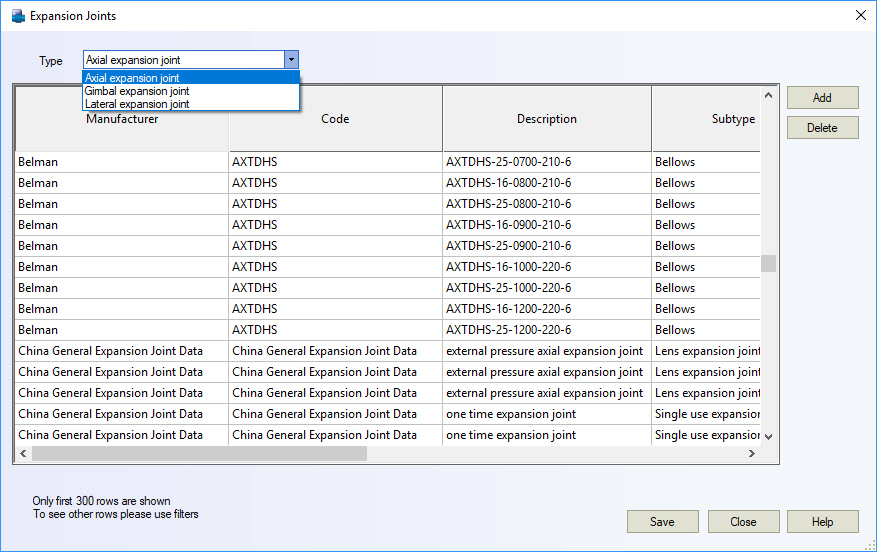

See Knowledge BaseExpansion Joints

Contains properties of expansion joints by different manufacturers:

- Axial

- Gimbal

- Lateral

- Universal

- Slip Joints

- Ball Joint

Insulation

Contains insulation weights

See Knowledge BaseTees

Contains tee properties that are needed for stress analysis according to ANSI, EN, GOST standards

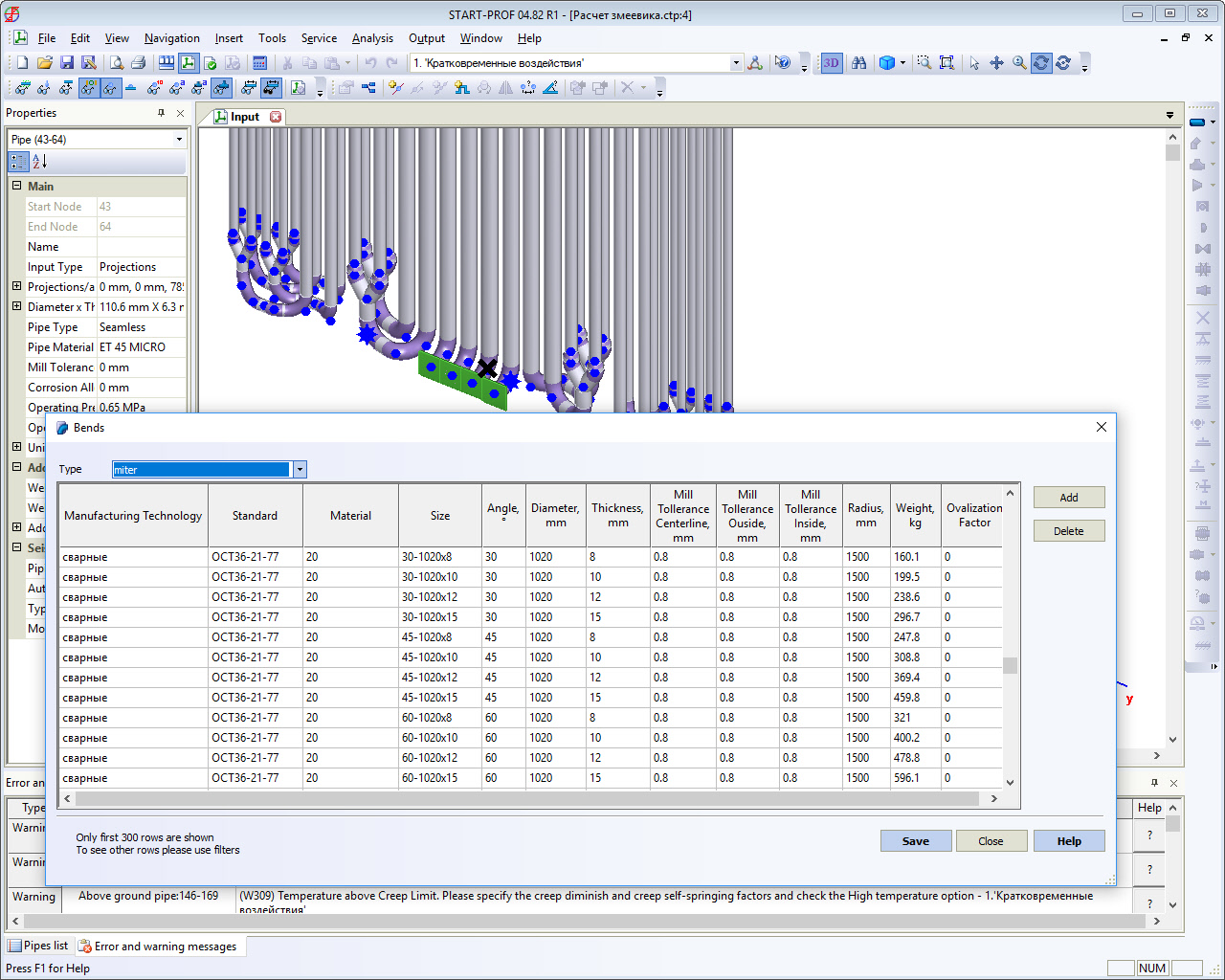

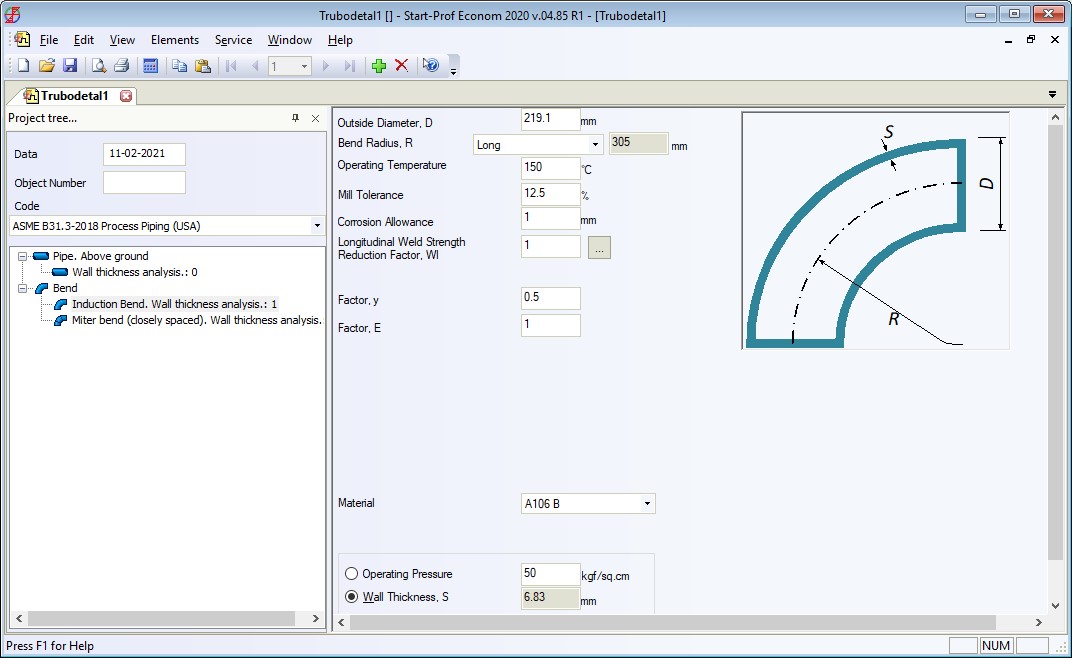

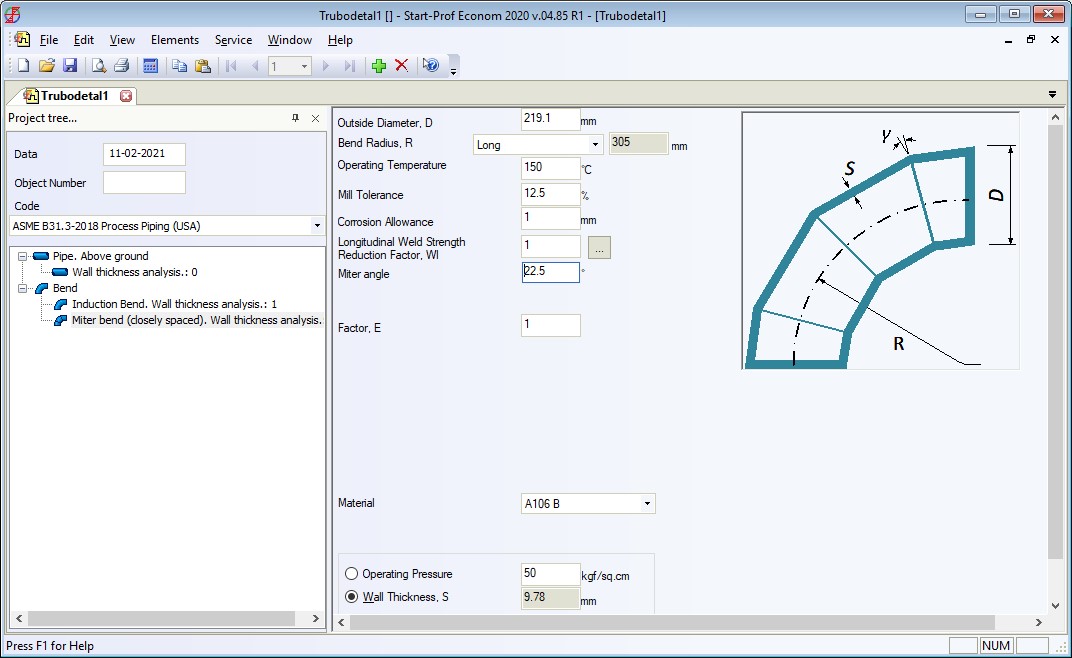

See Knowledge BaseBends

Contains bend properties that are needed for stress analysis according to ANSI, EN, GOST standards

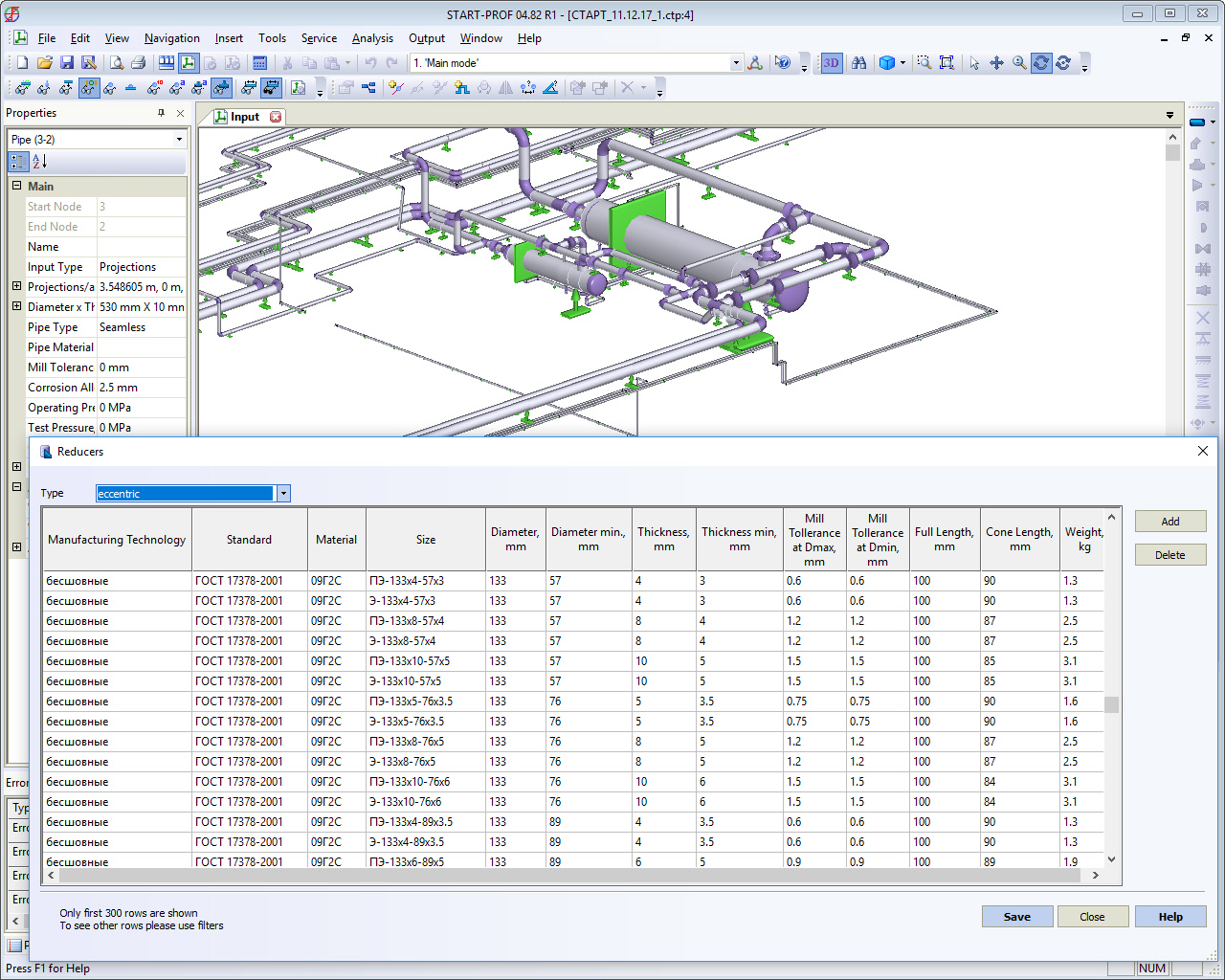

See Knowledge BaseReducers

Contains reducer properties that are needed for stress analysis according to ANSI, EN, GOST standards

See Knowledge BasePipes

Flange and Gasket

Databases "Flanges", "Single Flanges", and "Gaskets" contain all properties needed for pipe stress analysis and leakage check

See Knowledge BaseBeam

Contains all beam element properties required for stress analysis

See Knowledge BaseValve

Contains all properties required to model valve elements for pipe stress analysis

See Knowledge BaseUser Interface

PASS/START-PROF has a smart, easy and friendly user interface with user manuals in English, Chinese, and Russian languages. Fast piping modeling allows even the beginner without any special training to be able to perform pipe stress analysis.

An intuitive object-oriented piping model is used for easy modeling of piping systems that consists of following objects:

Pipes

- Above-groud

- Buried

- Rigid Element

- Cylindrical Shell

- Beam Element

- Cone Element

- Flexible Element

Bends

- Elbow

- Pipe Bend

- Miter Bend (closely-spaced)

- Long-radius Pipe Bend

- Prestressed Long-radius pipe bend

- Miter Joint (used for widely-spaced miter bend)

- Non-standard Bend with Manual SIF and Flexibility Factors

- Trunnion (bend with dummy leg)

Tees

- Welding Tee

- Reinforced Fabricated Tee

- Unreinforced Fabricated Tee

- Stub-in

- Weldolet

- Sweepolet

- Extruded Outlet

- Plastic and FRP tee

- Non-standard tee with manual SIF and flexibility factors ii, io, it, ia for run and header

Reducers

- Concentric

See Knowledge Base - Eccentric

See Knowledge Base

Restraints

- Anchor

- Hinged Anchor

- Sliding Support

- Spring Hanger with Rotation rod

- Spring Support with Friction

- Constant Effort Hanger with Rotation Rod

- Constant Effort Support with Friction

- Guide Support (Single-Direction, Double-Direction)

- Rigid Hanger, Rigid Stand with Rotation Rod

- Snubber

- Non-standard Restraint (any combination of Single-Direction, Double-Direction, Elastic restraints)

Expansion Joints

- Axial (Bellows, Lens, Slip Joint, One-time Compensator)

- Gimbal

- Lateral

- Untied

- Trosion

- Ball Joint

- Non-standard Expansion Joint

Deformations

- Different Types of Cold Spring (Cold Pull)

- Restraint Movements

Loads

Restraint Movements

See Knowledge Base

Valve

See Knowledge Base

Flange Pair

See Knowledge Base

Cap

Ballasting Weight

See Knowledge Base

Joint

See Knowledge Base

Equipment

- Cylindrical Shell

See Knowledge Base - Pressure Vessel

See Knowledge Base - Tanks

See Knowledge Base - Pumps API 610

See Knowledge Base - Pumps ISO 9905

See Knowledge Base - Pumps ISO 5199

See Knowledge Base - In-line Pumps

See Knowledge Base - Compressor API 617

See Knowledge Base - Turbine NEMA SM 23

See Knowledge Base - Fired Heater

See Knowledge Base - Air Cooled Heat Exchanger

See Knowledge Base

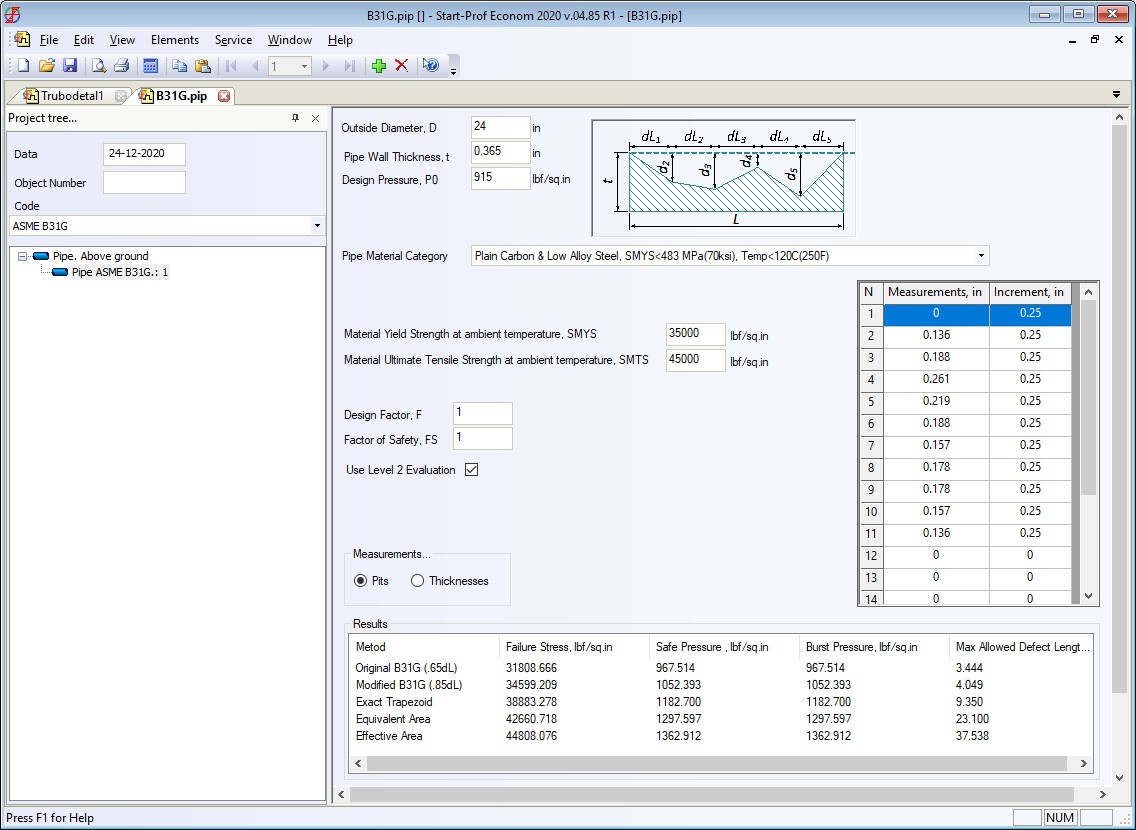

Flaw

- Plane Flaw

See Knowledge Base - Volumetric Flaw

See Knowledge Base

System Requirements

Codes

The following codes are implemented into Start-Prof software:

Power Piping

Central Heating

Process Piping

Gas & Oil

- ASME B31.4-2019 + Ch. IX & XI Liquid Transportation (USA)

- ASME B31.8-2020 + Ch. VIII Gas Transmission (USA)

- ASME B31.12-2019 Hydrogen Piping and Pipelines (USA)

- BS PD 8010-1,2:2015 Pipeline systems (UK)

- CSA Z662 + Ch.11 Oil and gas pipeline systems (Canada)

- GB 50251-2015 Gas Pipelines (China)

- GB 50253-2014 Oil Pipelines (China)

- SNiP 2.05.06-85 Gas and Oil Pipelines (Russia)

- SP 36.13330.2012 Gas and Oil Pipelines (Russia)

- GOST R 55989-2014 Gas and Oil Transmission Pipelines for Pressure Greater 10 MPa (Russia)

- GOST R 55990-2014 Field pipelines (Russia)

- SP 284.1325800.2016 Field pipelines (Russia)

Fiberglass Piping

Plastic Piping (PE, PE-RT, PP, PB, PVC, PVDF etc.)

- GOST 32388-2013 (Russia)

Other Piping

SIF and flexibility factors

Equipment Loads Check

- API 610 12th Edition, Centrifugal Pumps (USA)

- WRC 537 Local stresses in spherical and cylindrical shells due to external loadings

- API 617 9th Edition. Axial and Centrifugal Compressors and Expander-compressors

- API 560 5th Edition. Fired Heaters for General Refinery Service

- API 661 7th Edition. Petroleum, Petrochemical, and Natural Gas Industries—Air-cooled Heat Exchangers

- API 650 13th Edition. Welded Tanks for Oil Storage

- EN ISO 9905:1998+A1:2011 Technical specifications for centrifugal pumps — Class I

- EN ISO 5199:2002 Technical specifications for centrifugal pumps — Class II

- NEMA SM23 R2002 Steam Turbines for Mechanical Drive Service

- GOST 32601-2013, Centrifugal Pumps (Russia)

Nozzle Flexibility

Seismic Loads

- ASCE 7-22 (USA)

- IBC 2021 (International)

- NSR-10 (Colombia)

- KBC 2016 (South Korea)

- UBC 1997 (International)

- NBC 2020 (Canada)

- CFE 2015 (Mexico)

- EUROCODE 8 EN 1998-1 (European Union)

- IS 1893:2016 (India)

- AS/NZS 1170.4-2007 Amendment 1,2 (Australia / New Zeland)

- Seismic Code for Dubai (Dubai)

- ASCE 2001 Guidelines for the Design of Buried Steel Pipe (American Lifelines Alliance) (USA)

- GB 50032-2003 (China)

- GB 50011-2016 (China)

- SNiP II-7-81* (Russia)

- SP 14.13330.2018 addenda #1 (Russia)

- NP-031-01 (Russia)

- TKP EN 1998-1-2011 (Belarus)

- SP RK 2.03-30-2017* (Kazakhstan)

- KMK 2.01.03-19 (Uzbekistan)

Wind Loads

- IBC 2021 (International)

- UBC 1997 (International)

- ASCE 7-22 (USA)

- BS 6399-2 (Britain)

- EN 1991-1-4 2005+A1-2010 (European

Union) - NBC 2020 (Canada)

- GB 50009-2012 (China)

- IS.875.3.2015 (India)

- AZ/NZS 1170.2:2021 (New Zeland)

- NBR 06123-1988 (Brazil)

- CNS (Taiwan)

- NSR-10 (Colombia)

- KBC 2016 (Korea)

- CFE 2020 (Mexico)

- SP 20.13330.2016 addenda 3 (Russia)

- Dubai Wind Code 2013 (Mexico)

- Wind Pressure vs Elevation

- Wind Velocity vs Elevation

- Blast Load (DNV RP D101)

Snow Loads

Ice Loads

Fitness for Service

Integration

Start-Prof has interfaces with following design and analysis software:

| Software | Import into Start-Prof | Export from Start-Prof |

|---|---|---|

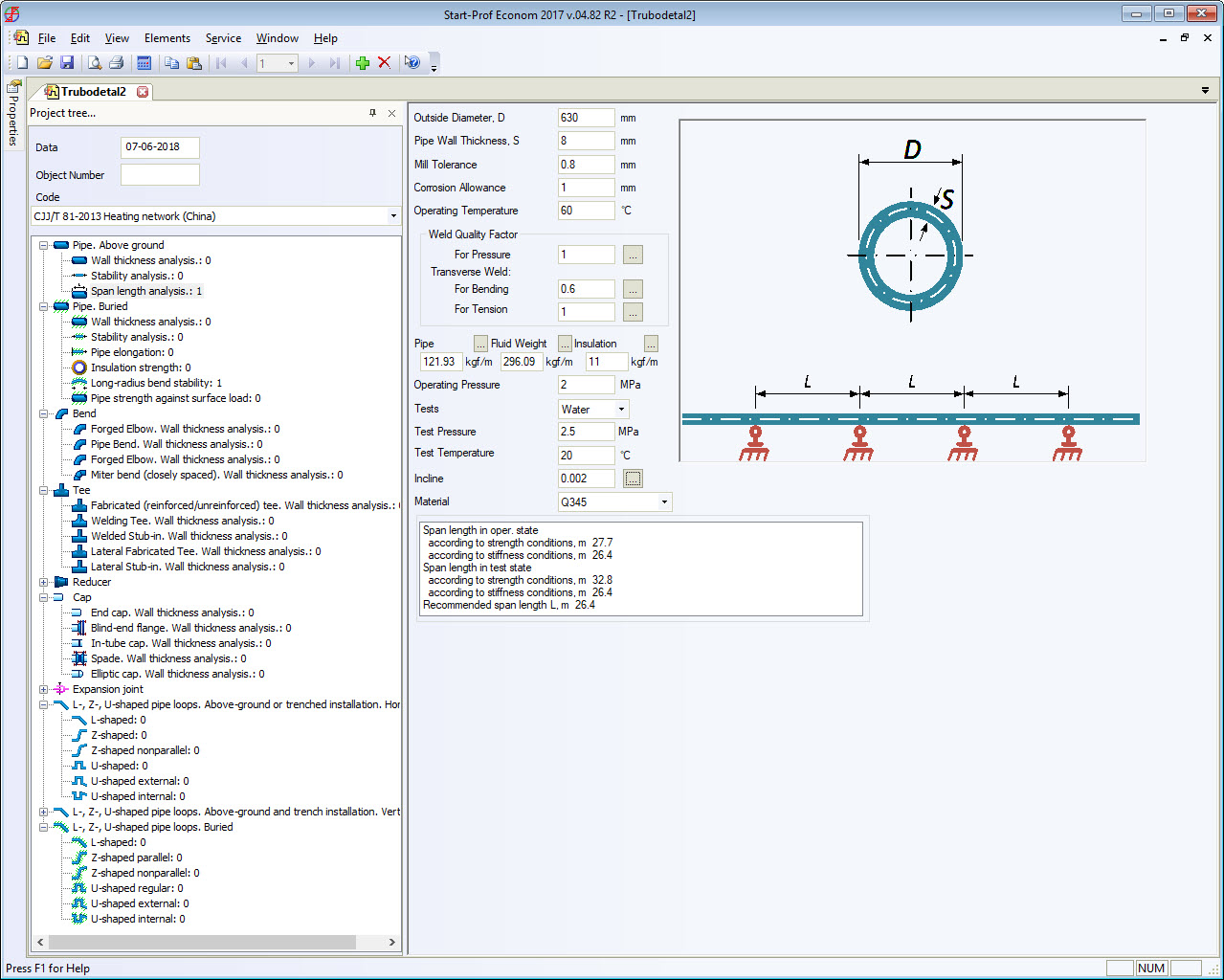

START-Elements - Express Analysis and Sizing

Along with the analysis of piping systems of any complexity, PASS/START-PROF performs a wide spectrum of calculations “on the fly” thereby helping piping designers to make the right decisions. PASS/START-PROF calculates pipe and fitting wall thicknesses, span lengths, as well as sizes of typical piping assemblies. It also checks flange leakage, pump and equipment loads, buried and above ground pipeline longitudinal stability, pipe wall stability under vacuum, and other loads.

Besides the analysis of arbitrary configuration pipelines, we have implemented a working tool along with a piping handbook for piping designer — a START-Elements option. PASS/START-PROF software is designed for rapid flexibility estimation of piping fittings, their strength and stability analysis.

START-Elements allows the user to do the following:

- Analyze stress of L, Z and U-shaped piping loops (buried and above-ground)

- Pipe and fitting wall thickness calculation or maximum pressure allowed according to the code selected

- Calculate maximum allowable distances between supports via strength and stiffness analysis

- Check general and local stability of straight and curved pipe elements under the thermal expansion, external pressure (vacuum) and soil pressure loads

- Calculate minimum pipeline laying depth for underground pipeline stability analysis

- Calculate maximum pipeline laying depth for buried pipeline by polyurethane insulation stress analysis

- Calculate allowable load on saddle support for large-diameter pipes

- Calculate allowable distances between single action (one time) compensators and their closing temperature

- Calculate bellows stiffness if the manufacturer’s data are absent

- Flange leak check

- Centrifugal pump load check per API 610 (ISO 13709), GOST 32601-2013 and Kellogg method (L.C. Peng Pipe stress engineering)

Configurations

PASS/START-PROF can be delivered in different configurations to evaluate the piping stresses, displacements, and support loads from thermal expansion, cold-spring, soil and support subsidence, and other loads according to applicable standards and codes.

PASS/Start-Prof Complete Advanced

Simulation and sizing for any piping network considering all applicable national codes.

PASS/Start-Prof Complete Standard

configuration includes only worldwide popular standarts.

PASS/Start-Prof Process Advanced

Simulation and sizing for piping networks based on applicable national codes for process plants as well as for gas and oil transportation systems.

PASS/Start-Prof Process Standard

configuration includes only worldwide popular standarts.

PASS/Start-Prof Power Advanced

Simulation and sizing for any piping networks based on applicable national codes for power generation piping as well as for central heating networks.

PASS/Start-Prof Power Standard

configuration includes only worldwide popular standarts.

PASS/START-PROF HDPE&FRP

Piping stress analysis of high density polyethylene and/or fiberglass reinforced plastic piping systems.

Configurations Comparison

| Code | Complete Advanced | Process Advanced | Power Advanced | Complete Standard (40% discount) | Process Standard (40% discount) | Power Standard (40% discount) | HDPE+FRP (40% discount) |

|---|---|---|---|---|---|---|---|

| ISO 14692 | |||||||

| HDPE Piping | |||||||

| ASME B31.1 | |||||||

| ASME B31.3 | |||||||

| ASME B31.4 | |||||||

| ASME B31.5 | |||||||

| ASME B31.8 | |||||||

| ASME B31.9 | |||||||

| ASME B31.12 | |||||||

| EN 13480 | |||||||

| EN 13941 | |||||||

| BS PD 8010 | |||||||

| CSA Z662 | |||||||

| GB 50316 | |||||||

| GB/T 20801 | |||||||

| GB 50251 | |||||||

| GB 50253 | |||||||

| GB/T 19624-2019 | |||||||

| DL/T 5366 | |||||||

| CJJ/T 81 | |||||||

| RD 10-249-98 | |||||||

| GOST R 55596 | |||||||

| GOST 32388 | |||||||

| SNiP 2.05.06-85 | |||||||

| GOST R 55989 | |||||||

| GOST R 55990 | |||||||

| SP 284.1325800.2016 | |||||||

| SP 33.13330.2012 | |||||||

| SP 36.13330 |

Download Software

| Software | Link | Upload Date |

|---|---|---|

| PASS/START-PROF 4.86 R4 (English) | request |

12.12.2023 |

| PASS/START-PROF 4.86 R4 (Chinese) | request |

12.12.2023 |

| PASS/START-PROF 4.86 R4 (Spanish) | request |

12.12.2023 |

| PASS/START-PROF 4.85 R7 (English) | request |

12.12.2023 |

| PASS/START-PROF 4.85 R7 (Chinese) | request |

12.12.2023 |

| PASS/START-Prof Student 4.86 R4 (English) | request |

12.12.2023 |

| PASS/START-Prof Student 4.86 R4 (Chinese) | request |

12.12.2023 |

| PASS/START-Prof Student 4.86 R4 (Spanish) | request |

12.12.2023 |

| PASS/START-Prof Student 4.85 R7 (English) | request |

12.12.2023 |

| PASS/START-Prof Student 4.85 R7 (Chinese) | request |

12.12.2023 |

| PASS/START-PROF Internet License 4.86 R4 (English) | request |

12.12.2023 |

| PASS/START-PROF Internet License 4.86 R4 (Chinese) | request |

12.12.2023 |

| PASS/START-PROF Internet License 4.86 R4 (Spanish) | request |

12.12.2023 |

| Free PASS/START-PROF Model and Result Viewer 4.86 R3 (English) | request |

12.12.2023 |

| Free PASS/START-PROF Model and Result Viewer 4.86 R3 (Chinese) | request |

12.12.2023 |

| Free PASS/START-PROF Model and Result Viewer 4.86 R3 (Spanish) | request |

12.12.2023 |

| Dongle Drivers (SafeNet Sentinel 7.6.9) | exe, 7.37 MiB | 13.12.2023 |

| Dongle Update (KeySt) for PASS/START-PROF | zip, 7.64 MiB | 13.12.2023 |

| LMS (Sentinel HL and Guardant) Tools (only for PASS/NOZZLE-FEM 3.5, PASS/HYDROSYSTEM 4.6 and PASS/EQUIP 3.7) | ||

| Dongle Update Tool (KeySt) for Guardant and Sentinel HL | zip, 16.76 MiB | 09.07.2024 |

| Drivers and network key manager for Sentinel HL dongles (Windows) | exe, 37.14 MiB | 12.12.2023 |

| Drivers for Guardant dongles | exe, 11.43 MiB | 24.12.2021 |

| SuperPro Tools | ||

| Dongle Update (KeySt) | zip, 4.13 MiB | 13.12.2023 |

| Dongle Drivers SafeNet Sentinel 7.6.9 | exe, 7.37 MiB | 13.12.2023 |

Resources

Videos

Supporting Materials

PASS/START-PROF Capabilities for District Heating Industry

PASS/START-PROF Capabilities for District Heating Industry (Spanish)

PASS/START-PROF Capabilities for Oil & Gas Gathering, Upstream and Midstream Pipelines

PASS/START-PROF Capabilities for Oil & Gas Gathering, Upstream and Midstream Pipelines (Spanish)

PASS/START-PROF Capabilities for Pipe Stress Analysis of Power and Process Piping Systems

PASS/START-PROF Capabilities for Pipe Stress Analysis of Power and Process Piping Systems (Spanish)

PASS/START-PROF Datasheet 2020

PASS/START-PROF Overview 4.84 version (Italian)

PASS/START-PROF Training Agenda

PASS/START-PROF Webinar for SPED Egypt Chapter December 2020

PASS/START-PROF Webinar. Lo nuevo en 4.85. Dinamico (Spanish)

PASS/START-PROF Webinar. What's New in 4.85. Dynamic

Additional PASS/START-PROF Resources

- PASS/START-PROF Version History

- PASS/START-PROF Online Knowledge Base

- PASS/START-PROF Application Guide

- YouTube Channel with lot of the training and overview videos

- LinkedIn Page where we share all the latest articles, videos and latest new about PASS/START-PROF

- Twitter Page where we share all the latest articles, videos and latest new about PASS/START-PROF

- Collection of more than 50 articles about pipe stress analysis and PASS/START-PROF

- Download Free Fully Functional Trial Version

- Ask your questions on PASS/START-PROF Forum